In the last few days, the press has published more accounts on the 737 Max and broader issues on Boeing’s safety culture, or more accurately, the increasing lack thereof.

Although all stories paint a broadly similar picture, that of a company that was relentlessly profit-oriented to the detriment of safety and adequate disclosure to regulators and customers, the most damning is a detailed piece at the Seattle Times, Engineers say Boeing pushed to limit safety testing in race to certify planes, including 737 MAX . I strongly urge you to read it full.

The article gives an incriminating account of how Boeing got the FAA to delegate more and more certification authority to the airline, and then pressured and abused employees who refused to back down on safety issues. On Monday, the Post and Courier reported about the South Carolina plant that produced 787s found with tools rattling inside that Boeing SC lets mechanics inspect their own work, leading to repeated mistakes, workers say. Oops! Another report at Reuters described how Boeing weakened another safety check, that of pilot input.

A new piece in the Wall Street Journal described how Boeing knew of 737 Max software problems a full year before it told the FAA, and how it also gave inconsistent accounts to important customers.

Boeing Undermines Safety

Based on how the FAA greatly weakened supervision in 2004, it’s a testament to the airline industy’s deeply internalized safety culture that Boeing-like results didn’t occur till recently. And by “Boeing-like results,” I mean corners-cutting opposed by the very personnel who were tasked with safety oversight. As the Seattle Times described, the problems extended beyond the 737 Max MCAS software shortcomings; indeed, none of the incidents in the story relate to it.

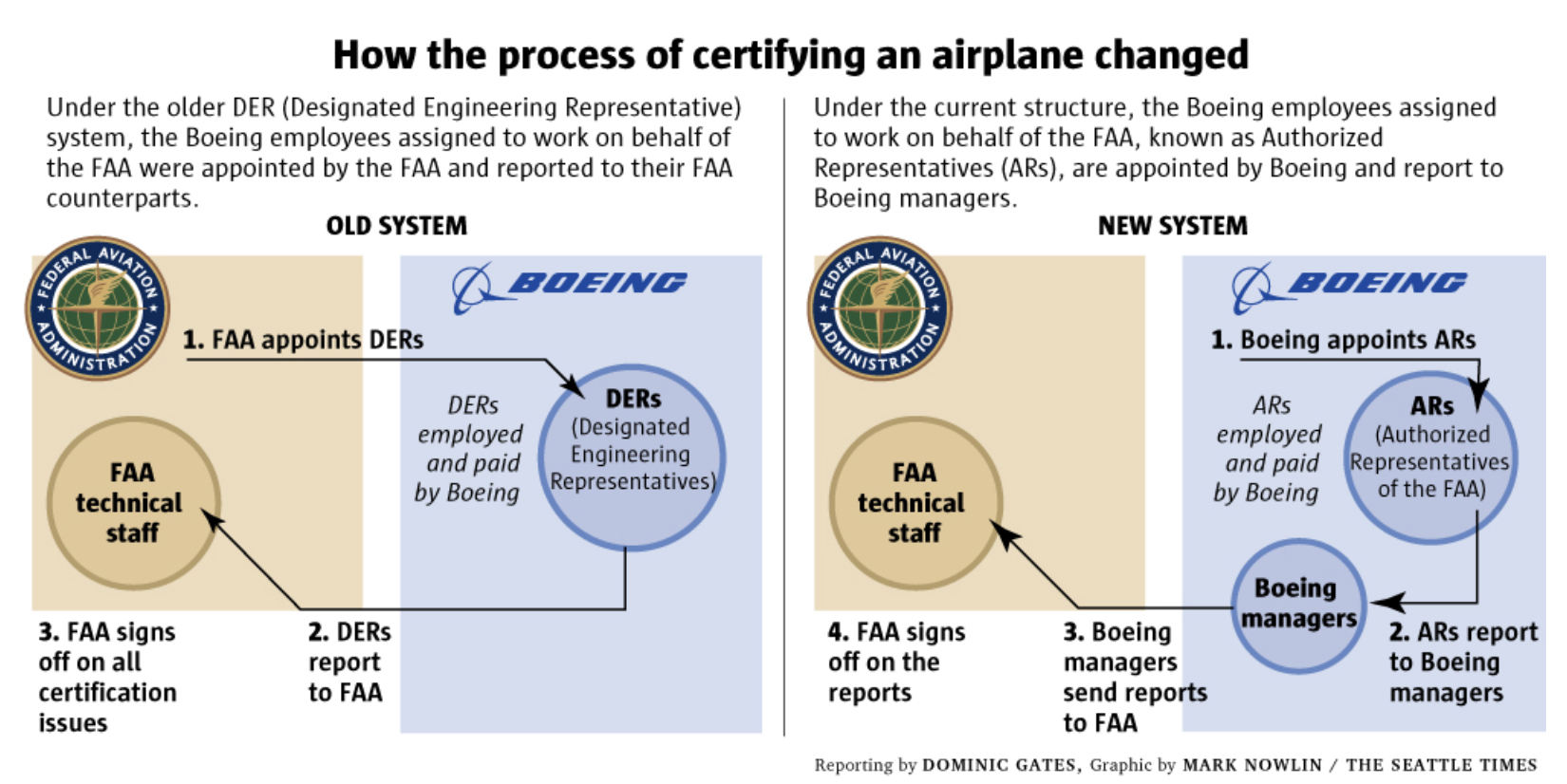

In 2004, the FAA changed its system for front-line supervision of airline certification from having the FAA select airline certification employees who reported directly to the FAA to having airline employees responsible for FAA certification report to airline management and have their reports filtered through them (the FAA attempted to maintain that the certification employees could provide their recommendations directly to the agency, but the Seattle Times obtained policy manuals that stated otherwise).

Some readers might see the old “Designated Employee Representative” or DER system as pretty dodgy too, as in why wasn’t the FAA doings all the work? As the article explains, people who stay at the FAA for more than a very few years get out of date on current airline technology. The old DER system reportedly worked well. Despite the obvious potential for abuse, the Authorized Representatives (ARs) were treated with respect at manufactures…except for Boeing.

The Seattle Times article describes how a Boeing AR was thrown off his job duties after refusing to back down on the need for more testing of fire-suppression equipment for the LEAP engines on the 737 Max even after other ARs confirmed his call. From the story:

“The ARs have nobody supporting them. Nobody has their backs,” said one former Authorized Representative who worked on the 737 MAX and who provided details of the engineer’s removal from the program. “The system is absolutely broken.”

FAA-designated oversight engineers are supposed to enjoy protection from management pressure. Removing one who proves a stickler for safety regulations will inevitably produce a chilling effect on others who see the consequences of being too rigid about safety concerns, said John Goglia, former member of the National Transportation Safety Board (NTSB).

“It negates the whole system,” said Goglia. “The FAA should have come down on that really hard.” …

While a few former employees involved in certifications said they handled the pressure as a regular part of the job, others described the work environment as hostile, focused on achieving FAA approval within schedule and cost targets.

And this wan’t the only incident. The Seattle Times found five other areas where Boeing muscling ARs in addition to the one above. Industry consultant Mike Levenson, who certified airline repairs for Boeing. Out of roughly 500 he reviewed, he refused to certify three. The first two objections led to him being called in by a supervisor for a chat. Then:

On the third occasion, in June 2013, a proposed repair clearly did not meet all FAA requirements, he said. After he declined to approve it, Levenson said, his manager “told me to go back and find compliance or my contract would not be extended.”

Mike Levenson, who has worked as an FAA representative at several companies and served in an AR role at Boeing for five years until 2013.

He said that while there’s always a pressure on FAA representatives in an aviation world full of deadlines and cost considerations, most industry managers are able to find a balance to ensure the ARs have independence. He said he didn’t find that to be the case at Boeing.

Levenson worked on certifying aircraft repairs at Boeing and said he certified more than 500 in his time there, though he did not work on the MAX. On three occasions, he declined to certify repairs. The first two times, Levenson said, he got called into a supervisor’s office.

On the third occasion, in June 2013, a proposed repair clearly did not meet all FAA requirements, he said. After he declined to approve it, Levenson said, his manager “told me to go back and find compliance or my contract would not be extended.”

Levenson agreed to do additional work and consulted with other colleagues but still couldn’t certify the repair’s compliance.

“When I reported this to my manager, I was told this was unacceptable and was summarily dismissed the following day,” Levenson said.

The Seattle Times had learned about the removal of the engineer who had raised red flags about the LEAP engines via a 2017 report filed by three unions representing Boeing technical employees. Again from the story:

….the incident was listed among a long series of problematic decisions made under the current system of delegating FAA certification and oversight to Boeing….

Four additional concerns specific to the 737 MAX were listed in the 2017 report. All were related to certification of legacy systems inherited from the earliest 737 models that were found by FAA technical staff to be noncompliant with the latest safety regulations.

These involved a lack of redundancy in the rudder cables; a too-high surface temperature allowed in the fuel tank; insufficient fireproofing around the plane’s auxiliary power unit in the tail; and using high-power wiring to connect to a switch inside the fuel tank.

All these issues were flagged by safety engineers working at the FAA as requiring fixes before the MAX could be certified.

The MAX won certification anyway after managers on the Boeing side of certification insisted that these were non-issues and managers on the FAA side agreed to let it move ahead with these shortcomings unaddressed.

And if that isn’t troubling enough:

“The (older) DER approach worked extremely effectively,” [John] Cox [chief executive of Safety Operating Systems and formerly the top safety official for the Air Line Pilots Association] said. “If engineers are working on behalf of the FAA, they should have a direct technical liaison with the FAA.”….

Yet before the MAX crashes, the FAA was heading in exactly the opposite direction: toward more delegation of oversight, with FAA participation reduced to a bare minimum.

A 2012 report to the FAA by a committee co-chaired by a Boeing representative and the FAA’s top aviation safety official, Ali Bahrami, recommended increased delegation of oversight to industry, working toward a “future state” beyond ODA with another deliberately obscure bureaucratic name: Certified Design Organization, or CDO.

If Boeing were to achieve CDO status, its employees could certify their own designs. Employees doing the certification work would not be designees technically working on behalf of the FAA, just Boeing engineers working for Boeing.

This would be true self-certification, but has not yet been implemented.

But actually, aAt the South Carolina 787 Dreamliner factory, 90% of the aircraft were self-inspected.

Now technically, this probably would not be considered “self-certification” since the self-inspection is taking place on a mature airplane design. As the Post and Courier tell us:

Some of the mistakes are serious safety hazards, like debris being left in the sensors that measure air speed while a plane is in flight. More common problems, workers say, range from surplus rags and bolts left in planes to loose cabin seats and unsecured galley equipment.

Workers say many of those production problems can be traced to the relatively new self-inspection program now spearheaded by Boeing Vice President Ernesto Gonzalez-Beltran, a former automobile executive with no previous aviation manufacturing experience.

The lean manufacturing approach Gonzalez-Beltran is working to incorporate at Boeing drew similar complaints and a lawsuit at a California auto plant he once helped manage.

“I’m always finding cases where jobs are signed off and the parts aren’t installed,” said a Boeing worker, who asked not to be named for fear of reprisal. “It happens a lot.”…

One worker said planes have been moved out of final assembly with cut tires, cooling fluids that haven’t been serviced, gears that haven’t been tested and hydraulics that aren’t fully functional.

“They are rolling them out on the day scheduled no matter the condition,” an employee said. “The schedule on paper drives everything here now.”

Even though Boeing has succeeded in reducing the time in final assembly considerably at this plant, the average number of days from final assembly to first flight has increased by even more days, so it’s not clear that all of this corners-cutting is leaving Boeing net ahead. The story describes at length how managers press workers not to submit reports of quality problems, and when they do, they are often ignored or cancelled.

And Boeing plans to slash the number of inspectors at this and other plants:

Boeing plans to eliminate 451 inspectors at West Coast plants this year and a similar number in 2020. About 100 inspection jobs are on the line in North Charleston.

Recall how, last week, the Wall Street Journal described a Boeing 737 Max safety shortcut, that of limiting pilot input:

Boeing Co. limited the role of its own pilots in the final stages of developing the 737 MAX flight-control system implicated in two fatal crashes, departing from a longstanding practice of seeking their detailed input, people familiar with the matter said.

As a result, Boeing test pilots and senior pilots involved in the MAX’s development didn’t receive detailed briefings about how fast or steeply the automated system known as MCAS could push down a plane’s nose, these people said. Nor were they informed that the system relied on a single sensor—rather than two—to verify the accuracy of incoming data about the angle of a plane’s nose, they added.

Boeing Plays Cover Up

We described early in the 737 Max fiasco how Boeing was breaking the well-known rules of crisis management by doubling down on its claim that nothing serious was amiss. As we wrote:

Boeing is breaking the rules of crisis management and making what may well prove to be a bad “bet the company” wager….

Boeing is taking steps that look designed to be adequate, when given the damage done to the 737 Max and its brand generally, this isn’t adequate. No one has any reason to give Boeing the benefit of the doubt. The scale of this failure is so large that it’s called the adequacy of FAA certifications into question. Until this fiasco, aviation regulators deferred to the judgment of regulator in the country where the manufacturer was headquartered. But with China embarrassing the FAA by (correctly) being the first to ground the 737 Max, foreign regulators will make their own checks of Boeing’s 737 Max fixes….and that practice may continue with other US-origin planes unless Boeing and the FAA both look to have learned a big lesson. So far, Boeing’s behavior says not.

It’s now clear that Boeing has been in minimal disclosure mode on the 737 Max for some time. ,The Wall Street Journal this Sunday described how Boeing couldn’t be bothered to be truthful with its customers or the FAA:

Boeing Co. didn’t share information about a problem with a cockpit safety alert for about a year before the issue drew attention with the October crash of a 737 MAX jet in Indonesia, and then gave some airlines and pilots partial and inconsistent explanations, according to industry and government officials.

It was only after a second MAX accident in Ethiopia nearly five months later, these officials said, that Boeing became more forthcoming with airlines about the problem. And the company didn’t publicly disclose the software error behind the problem for another six weeks, in the interim leaving the flying public and, according to a Federal Aviation Administration spokesman, the agency’s acting chief unaware.

The Journal restrained itself, waiting till close to the end of the article that the acting head of the FAA, Daniel Elwell, didn’t know that Boeing had been shipping 737 Maxes with inoperative angle of attack disagree alerts prior to reading it about it in the Journal.

The New York Times and ABC (Australia) also investigated how Boeing misinformed Southwest. Lambert graciously added footnotes to ABC’s account:

In manuals[1] that Boeing gave to Southwest Airlines — the biggest operator of both the MAX and 737s in general — the warning light was depicted as a standard feature just as it is on older 737s, according to Southwest spokeswoman Brandy King.

After the Lion Air crash, Ms King said, Boeing notified Southwest that it had discovered[2] the lights did not work without the optional angle-of-attack indicators, so Southwest began adding the optional feature too.

That allowed the airline to activate the sensor-disagree warning lights on its 34 MAX jets earlier this year, she said.

Ms King described both features as “supplemental” and “advisory” to other information provided to pilots during flights.

The indicator was designed to tell pilots when sensors that measure the pitch of the plane’s nose appeared to conflict, a sign that the sensor information is unreliable.

Boeing told airlines that the warning light was standard equipment on all MAX jets.

Boeing engineers quickly learned[3], however, that the warning light only worked if airlines also bought an optional gauge that told pilots how the plane’s nose was aimed in relation to the onrushing air.

Boeing said the problem stemmed from software delivered to the company.[4]

Needless to say, some customers are not very happy:

Dubai's top aviation official slams Boeing for its handling of the 737 Max grounding https://t.co/VkmVKzKCEQ

— Bloomberg (@business) May 4, 2019

And it is hard to see how Boeing recovers its reputations with coverage like this. Watch the opening segment of this 60 Minutes Australia show, which starts with a 737 pilot narrating what happened in the Lion Air crash in a 737 simulator:

Shorter: Boeing is in a very deep hole and just keeps digging.

____

[1] There has already been discussion about documention and manuals being out of synch (a constant danger in the tech doc world) but if they are out of synch due to Boeing self-certification that’s an issue

[2], [3] If this is true, then the product versioning theory shared by Lambert and some readers is not true

[4] It had appeared that Boeing outsourced the MCAS software to Rosemount, but apparently they only built the AoA sensor and the software was outsourced to Collins. This is from April 5:

How long until Boeing goes under? It just keeps getting worse and worse.

This is an American, well connected company , to big to fail for both military and commercial aviation. I would be suprised if there are consequences. Which is what we are used to, no?

Going under?

Its state sanctioned enterprise.

Think Tesla on steroids.

Its NEVER going under. Just like the TBTF banks.

BTW, US and China fairly similar these days: one’s state sanctions business and the other’s state owns the business. Fine line between the two, especially when the gov and wall street become closer and closer to singularity. I mean US gov is flooded with ex-Wallstreet execs. Like FAA and Boeing. One big club of sanctioned net profits, kickbacks, and collusion.

The 737 is Boeing’s most profitable airplane. Talk about shooting yourself in the wallet. Remember that in American aviation, only corporate executives get golden parachutes.

I like that idea. Gold is one of the densest metals. Put that exec on board one of the company’s planes with a gold parachute and give everyone else a regular nylon parachute. Then when the plane catches on fire in mid-air the executive plummets straight to the ground while the rest land safely.

Well when 80% of your wallet is filled with Gov contracts, it actually doesnt hurt too much.

Hence, the barely rattled Boeing stock.

VW fared far worse with Diesel Gate.

I do wonder when the China says that no aircraft certified by FAA can fly in its airspace, until someone else re-certifies it…

That said, I heard some very very similar stories about Suchoi S-100 aircraft which burned in Moscow last Friday (pushed into production despite numerous flaws for political reasons). Lightning strike on an aircraft is literally hourly eve – there’s no hour during the day when at least one aircraft would not be struck by lightning. I was a passenger in small ATER-42 turboprop when it flew through a storm and I’m sure was hit by lightning. Wasn’t pleasant, was scary for my small daughter, but it handled it ok.

Unfortunately, the push to get out incomplete and bad stuff is all around us (be it for profit, political reasons or whatever), but in cases like this, it’s deadly.

Here’s a fun fact. I found that Boeing was a consultant to Suchoi on the development of S-100! Talk about exporting crapification..

Its kind of interesting the way the Superjet originally used multiple European and US partners in design and construction, but it is now being ‘Russified‘ as a protection against sanctions. I think the major US contractor is for the hydraulic system. I wonder if this is a factor in making it less safe – Russia just doesn’t have the overall manufacturing ecosystem for an aircraft of this complexity (arguably, no single country, including the US, does).

I am not sure about lack of Russian ecosystem. Are their military acft dependent on imported sub-systems? During the soviet block era some categories of aircraft were outsourced the various block countries.

I’m beginning to think that we need a new term for describing crapification. Call it a Matryoshka doll of crapification. Instead of just straight out crapification, this sort has layer upon layer of crapification as you delve into the inner workings. I happened to catch most of the 60 Minutes doco on this plane and after reading how these things were built by Boeing, I am not surprised at how bad they turned out. So, putting this all aside for the moment, I was considering what would happen when Boeing and the FAA try to bring back the 737 MAX into worldwide service again.

So the FAA certifies that all is well with the 737 MAX and that it is good to go. Cue the ribbon-cutting ceremonies and the popping champagne bottles. Perhaps the FAA even twists the arm of Transport Canada to certify the 23 planes that Air Canada has parked on their tarmac so that they can fly to. So where exactly do they fly to? There is a page at https://en.wikipedia.org/wiki/List_of_Boeing_737_MAX_orders_and_deliveries which shows who has these planes on order and who has already received delivery of them.

So the first half is to get those countries to certify that these planes are good to go after Boeing has weaved their magic about. That is if they will and I can imagine that Trump might threaten those countries that do not allow these planes to fly by denying reciprocal landing rights or something. The second half is more complicated. What about those countries that have these planes overflying them but do not use them. The UK may say that they will let them fly but will France or Belgium or Hungary let these planes over their territory with the potential of a crash. More to the point – which country now trusts the FAA still and will take them at their word? That model got broken and until they can rebuild a safety culture – which will take years – aircraft verification is going to problematical at best.

Fractal crapification? From https://rationalwiki.org/wiki/Fractal_wrongness :

Same idea.

I’ll have to remember that term. It sounds very useful.

I was reading today how much more efficient Boeing is in manufacturing their planes as compared to Airbus in terms of costs and profits per plane.

Well, the recent stories coming to light really seem to explain that.

There was great discussion two or three years ago on a European aviation website (maybe PPRUNE or Airliners.net) where some ill-informed American who alligator mouthed got a well presented lesson on cost comparisons by fact backed Europeans. A splendid take down of dogma.

Maybe there is a Peter principle for crapification; crapification rises to its maximum level of incompetence until a disaster happens.

An element of this scandal that seems little discussed is that Boeing fired many of its engineers at some point to save money. Did this firing damage the company’s ability to design new airplanes? How many engineers are optimal?

a company that was relentlessly profit-oriented

And yet what better way to reduce your profits than selling dud equipment? Especially when dud = dead.

I’ve always found the quasi-religious aspect of managerialism simultaneously absurd and threatening.

Late Cretaceous American capitalism, in short.

As a former contractor for hot water and air heating systems, water supply and disposal systems for commerical and residential installations I am always astonished how any industry that has to make sure that its products are safe and the lifes of hundreds depend on safe products can afford to make shortcuts.

One problem – as with Boeing now – and you threaten everything you have build up.

Our systems were powered by natural gas, and I never left a job until I was 100% sure there were no leaks and all installations wered done in a way they were safe and tamper free as much as was technically possible. The thought alone that a gas leak could cause any damage to property and life kept us on out toes to check and check again and follow “best practices” and code stipulations of course.

After every job I went on the way home through what I did, and when I thought I might have missed something or could not remember the result of the check – I went back, even if it was an hour drive, and checked again.

The quip: Better safe than sorry” does seem to have little meaning any more.

There is an attitude problem that standards are there to be circumvented.

perhaps there is a connection between “crapification”, “over”population and monopolies?

Made me think again of those U-comics about Fat Freddy’s Cat and the cockroaches. Once in a while some 50.000 or so roaches would be killed by some hostile event and someone would ask their ruler: “So many have been killed, shouldn’t we hold mourning services?” to which the ruler usually replied: “Why? There’s still millions of them”…

The policy was set by a management that only sees $$$, not the people doing the actual work.

Management sets the policy with the assurance the US gov will not regulate and will not punish the biggest, or even the medium sized corporate dangers to public health and safety.

Imagine the govt coming out in support of the anti-vax campaign. That would be much the equivalent of the govt’s current de-regulation campaign. imo.

Crime pays in the United States. The people who win are the ones willing to do this kind of thing, at least for a while.

The checks and balances don’t work anymore, and it is up to the voters to reign in this misbehavior. This is slowly happening.

Like my Dad always used to say: “It is generally better to do a thing right, than to do a thing quick.

In program management, the quip usually goes: “Cost, schedule, and performance – you can have two of the three.” Maybe it should now be changed to: “Cost, schedule, and a safe product …….”

Adding a fourth element of ‘maximum Boeing executive compensation’ to that formula might be necessary.

Otherwise known as Cheap, Good, Fast

FAA decided replacing its DERs with Boeing appointed ARs wasn’t likely to put the ARs in the same unprotected catagory as whistleblowers as far as the company was concerned?

(There’s a long history of company retaliation against whistleblowers.)

Right.

Who was head of the FAA in 2004? Ah, Marion Blakey, (not a licensed pilot). After her stint as head of the FAA she became chief executive of the Aerospace Industries Association, an American defense industry trade association.

Cozy revolving door there. Sorry about those passengers…

adding: putting names to decisions or responsibility for decisions seems important. No more ‘faceless bureaucracy’ that acts like a personal shield for the people responsible for terrible decisions. imo.

Yes!. And the article above signals that there is personal responsibility here and there. These now want to be shielded by Boeing but they should be signalled and subjected to public scrutiny. It is the only way to clean the mess.

Just like Teresa Reed the fire chief in charge of inspecting properties in Oakland. Left with multiple pensions after 36 people were killed in a fire that was easily preventable.

https://www.mercurynews.com/2017/03/14/oakland-fire-chief-teresa-deloach-reed-retires-sources-say/

An American DEFENSE Industries Association. Explains something?

Well let’s put the blame where it belongs. This Congress’s mess. Now they have been pushed to do it by Boeing, but they chose to do it. Probably because it got rid government workers and made business happy. But will they be held accountable? No why do you ask?

Ii is also my understanding that the DERs were union employees and Boeing was unable to deliver airplanes during an engineer strike in 2000. The ARs are not union employees. More union busting by Boeing.

Guess, it sorta depends on what you’re actually selling? US capital equipment used to be very good. It had to more or less conform to specification, or the client sued you or fled to multinational competitors. Consumer items were just shiny baubles meant to sell the real product, the mark, debt. Alfred P. Sloan sprinkled on planned obsolescence, to sell 1920’s technology to generations of eager suckers & perpetuate lateral growth of repair, financing, insurance…

https://timeline.com/gm-invented-planned-obsolescence-cc19f207e842

https://www.vulture.com/amp/2019/05/chernobyl-hbo-mini-series-review.html

Wow, now comments are posting to the end of the thread?

Surely, in a free market, Boeing’s catastrophic failures, will be a call to action to the flying public to not choose the fly the planes they fly on.

The death of passengers on those fatal Lion Air and Ethopian Air should fall square on their own shoulders and not Boeing or the airlines. Those passengers failed to do due diligence, when purchasing their tickets, in evaluating the design and safety feature of the planes they choose to fly on. Clearly, only a fool would fly on a plane that relies on malfunctioning safety feature that is intended to overcome a design flaw in a plane that was rushed to market.

Sort of hard to do that, unless your aerospace,engineer isn’t it and have access to the plans and the time to review them ? Sounds like expecting non doctors to understand what treatment for heart failure is appropriate for them?

Same crapification, different industry:

Six Years Ago, He Helped Expose VW’s Diesel Fraud. This Year, G.M. Let Him Go.

The guy was a PhD student at UWV and built the instrumentation that discovered VW’s cheating. Cost VW $33B. I guess NO corporation wants this sort of employee around…

Thanks for post. As for

surely it must be increasingly clear to all that bad management is Boeing’s biggest problem. And as we’ve seen with the F 35 at Lockeed-Martin, it’s not just Boeing. The MIC is not only picking the taxpayer’s pockets but its increasingly concentrated and TBTF status is creating a culture of corruption and incompetence that is endangering civilian lives to go with all those third world conflict victims that our weapons makers profit from.

Airplanes to automobiles ok

Automobiles to airplanes??

How is society going to deal with software to automobiles, airplanes, Uber airtaxis, Amazon drones everywhere?

There Probably needs to be a rule that when corners are cut on an airplane, the executives must fly in that plane for a week.

The truth is, though, that corporations kills many people to save $$$, but the deaths are not as dramatic as a plane crush and don’t anger the public. A recent labor union report arrived at a figure of 95,000 U.S. deaths caused by shoddy business practices, I think.

Fine reporting Lambert.

I wonder if Muilenburg is going to admit he has found “a flaw in his worldview”?

lol. He and Greenspan can get together to discuss the fine character and nature of foxes. /s

Um, this was my post. I’ve written most of the 737 Max posts. Genderism on display?

I’ve been following Juan Browne’s coverage of the 737 MAX. Although he has a 737 rating, he currently flies the 777 as a first officer. Link to his video playlist:

https://www.youtube.com/playlist?list=PL6SYmp3qb3uPp1DS7fDy7I6y11MIMgnbO

As the ST reports today, Dennis Muilenberg, since his ascension to CEO, has doubled down on re-orienting Boeing culture from Engineering/Quality to “enhancing shareholder value”, and has he ever. But, of course, it’s all come at a cost, and the MAX clusterf**k brought it all to a head, with nonstop press revelations, Boeing denials, and what can conservatively be described as a “crisis of confidence” in management claims:

Crapification began wth expansion to South Carolina and the “Dreamliner” fiasco, and regrettably that mindset found its way back to WA, and here we are today.

“Dennis Muilenberg, since his ascension to CEO, has doubled down on re-orienting Boeing culture from Engineering/Quality to “enhancing shareholder value”

The MAX disaster just keeps getting worse and worse showing what seems to be widespread rot and decay at Boeing. At first it looked to me like it may have been a case like the 767 thrust reverser system flaw (mistaken assumptions in the failure state testing leading to a fatal accident) but it seems like the culture of the company has been thoroughly crapified over the recent years. Boeing is too important a company, especially in the military realm, for it to die no matter what happens to sales and I doubt anyone higher than middle management will pay any price whatsoever for this fiasco – actually given the share price rise I would be willing to bet the executives will have profited from it.

I was unaware of the changes to the DER system until you brought it to light in this article Yves – very troubling indeed. Thank you for writing about it.

> Crapification began wth expansion to South Carolina

Crapification began with union-busting, which was the reason for the expansion.

The Australian 60 Minutes Boeing expose is fascinating on all levels. A good old fashion exposure of deep corruption, criminality and tugs at the heartstrings. Something I have not seen of American TV in decades and do not expect to see again until the media empires are broken up. The real collusion is between American Oligopolies who control markets, media, financing and the government. The New World Order is fatal to the American and British middle-class and “Others” across the world. The overwhelming incompetence that kills people appears to have forced some Australians to have second thoughts about the special relationship with the USA. After all, selling raw commodities to China is their bread and butter today.

America has become nothing but a cesspool of liars and cheats screwing even one another to drain all pockets to themselves. There is no honor left in this country. Boeing deserves to be broken over this as do quite a few American corporations in their grand deceit and theft. A government that enables and wont even prosecute this kind of crime anymore is even more damning in the worlds eyes.

A possible fuel-air bomb in an airliner. Jesus, at some point it changes from greed and crappification to insanity driven avarice.

You saw that too. I read that along with ‘a too-high surface temperature allowed in the fuel tank; insufficient fireproofing around the plane’s auxiliary power unit in the tail’. Anything to do with flames they just pushed by. So even if the solve the software problem that hides the center of gravity problem, all these other issues are built into the fabric of those 737s. It’s an Edsel.

A Ford Pinto might be a better choice. It tended to cremate its occupants after minor fender benders.

> high-power wiring to connect to a switch inside the fuel tank

What could go wrong?

From Hacker News comments https://news.ycombinator.com/item?id=19832896 :

ken 2 days ago [-]

They did! 5 years ago, Al Jazeera made a documentary about Boeing’s problems [1]. Choice quotes from the first two minutes:

– “They’re shortchanging the engineering process to meet a schedule.”

– “We uncover a whistleblower fired as he fought for safety.”

The very things that you wonder why they never happened, did in fact happen.

[1]: https://www.aljazeera.com/investigations/boeing787/

I just read in my local paper that Boeing is planning to dismiss 900 inspectors, company wide, to be replaced by AI (artificial intelligence). For a moment I thought I was reading the Onion, but no. Could the timing possibly be worse for a move such as this? Naturally the union representing those inspectors is complaining loudly, as they should. I wonder what Boeing’s customers and their customer’s customers think about this move. My next trip is going to be on Amtrak.

After my last family visit via jet turned into an… interesting adventure, I thought about using Amtrak but besides being slower it is seems to be at least as expensive as flight. We live on different coast and I don’t think I can spend several days traveling while spending the same or more. Granted not having to deal with the joyful experience of the TSA would be worth something extra.

If they “app-ify” the engineering, they could use some AI software to partition along the interfaces and then distribute the design of millions of components into a crowd of “gig-engineers”, each engineer designing a part for a few hundred dollars. Then the AI re-assemble all the components into procurements, contractors build the assemblies, other contractors integrate those assemblies into an aircraft and the AI auto-certifies it.

Kinda like Amazon Mechanical Turk, only on a more advanced level.

Boeing could maybe reduce the entire company to 200 people; about 150 in systems engineering, 40 management and 10 in IT support?

I gave up flying on commercial aircraft in 1995, never missed it one bit.

Can’t help but wonder if Boeing would have kept on a more honest path if Mullaly hadn’t been passed over twice for the CEO post after the forced exits of the previous two CEOs, passed over in favor of a McKinsey and GE vet.

It would be “funny” if SWA were to switch to ‘Bus planes, forcing Boeing to focus on their military hardware and lobbying operations. Not going to happen, but still….

As has been written elsewhere, the 37 is a 50 year old design, first flew in ’67. Boeing was reportedly working on a replacement when the 320NEO came along and threatened to eat BA’s lunch so a quick decision ensued to MAX out the 37. Apparently one issue was the financial overhang of the development costs of the 87 though it would seem to this non-aviation engineer that they could have applied those costs to a new single aisle 37 replacement.

In the end it may cost them a large pile to settle the legal issues likely to ensue from the two MAX disasters. Likely that those who made the decisions won’t be paying the costs.

The Onion nailed it: https://www.theonion.com/5-things-to-know-about-boeing-s-ongoing-issues-1834478172

As someone who first flew as a passenger in a 737 way back in 1970, and indeed every Boeing model since then, I am just gobsmacked as to what has happened with the 737max project.

Remembering the car I drove in 1970 and contemplating stretching it to accommodate 10 people instead of 5, fitting a huge engine up front, with the extra seats in an overhang at the rear and fitting a massive gyroscope which would operate if the car was driven to extremes … you get the 737max picture.

All max aircraft should be returned to the USA and if their pilots want to fly them and passengers want to fly in them within the USA, fine by me. But me go in a max? No way Jose!

Kludge – that is the engineering term you guys are looking for to describe the 737-Max

It means to take an old system/design and make layer upon layer of modification until it basically can’t function in its original state – a kludge is something so larded up with old and NEW things that it becomes a Schrodinger Cat of sorts, so complicated it can’t be untangled, systems/fixes working against other older systems/fixes.

I come from a family of engineers and live in Seattle, Washington, and also in the flight path of Boeing field. And I can tell you, not for sure, but I think I saw Dennis Mullenberg flying overhead weeks after the grounding of 737-Max, testing out the (unmarked) Max with its new MCAS software fix.

You can recognize a Max by its short wings with its tips that are bifurcated, and its steep angle of attack when it takes off. What you can tell even from the ground is that big, “fat lazy pig”, as some pilots like to call the Max, it doesn’t want to fly. You can tell its going full speed and nose up just to get to altitude.

That’s because the engines are too far forward to give it any lift. Basically this plane does not want to fly, its getting up on all thrust.

Well, with the MCAS system secretly installed, and with the SOP of a Max, nose up, full speed, its going to activate the AOA sensor and tell the computer that it is stalling.

Now this kludge has become deadly – systems operating in contradiction of themselves.

The 737 single-row design is based on the 707 design from 1952, so in reality the kludge is almost 70 years old. So many design systems have been larded on this plane its dozen plus assignations that it can’t do what it was originally designed to do.

That is FLY.

We need to call it what it is….

The 737-Kludge

The 737 Kludge-Pinto?