By Jerri-Lynn Scofield, who has worked as a securities lawyer and a derivatives trader. She is currently writing a book about textile artisans.

New right to repair rules for some consumer electrical goods, including hairdryers, refrigerators, television displays, and washing machines, came into effect in the 27-nation EU on Monday, mandating that products be repairable for ten years.

Tech Republic reported that the the European Parliament voted to approve the policy in November 2020.

Each year, Europeans produce about 35 kilos of electrical waste per person, about half of which comes from household appliances, of which only 40% is recycled, according to Tech Explore. The EU new right to repair rules aim to reduce that waste.

As per Tech Xplore:

“This is a really big step in the right direction” said Daniel Affelt of the environmental group BUND-Berlin, which runs several “repair cafes” where people can bring in their broken appliances and get help fixing them up again.

Modern appliances are often glued or riveted together, he said. “If you need specialist tools or have to break open the device, then you can’t repair it.”

Lack of spare parts is another problem, campaigners say. Sometimes a single broken tooth on a tiny plastic sprocket can throw a proverbial wrench in the works.

“People want to repair their appliances,” Affelt said. “When you tell them that there are no spare parts for a device that’s only a couple of years old then they are obviously really frustrated by that.”

Going forward, manufacturers serving the EU market will need to supply spare parts for a minimum of ten years. The rules allow manufacturers to supply some parts to professional repair companies only – rather than directly to consumers – to ensure they are installed correctly. But providing explicitly for third party repair services to get access to parts reduces the stranglehold manufactures currently have on the pricing and availability of repair.

And, according to Tech Xplore:

New devices will also have to come with repair manuals and be made in such a way that they can be dismantled using conventional tools when they really can’t be fixed anymore, to improve recycling.

Some manufacturers – most notoriously, Apple in the consumer electronics area – use special screws that require specialized equipment to repair. I haven’t delved into how the EU expects to enforce this provision, but it is a sign of progress to see it enacted into law.

Europe is slowly expanding its waste management policy, so as to flesh out a circular economy models, with manufacturers required to consider a product’s entire life cycle, and an emphasis on sustainability. This model discards the prior linear model, which culminated in a product’s disposal.

Over to Tech Xplore:

German Environment Minister Svenja Schulze said that in a next step, manufacturers should have to state how long a product is expected to work for and repair it if it breaks down earlier. This would encourage companies to build more durable products, she said.

“In the repair cafes we see a lot of devices that broke shortly after the warranty expired,” said Affelt—a phenomenon that has prompted some environmentalists to accuse manufacturers of designing their devices with planned obsolescence.

Knowing an appliance will really last for a decade might prompt consumers to choose products that are more durable or can be easily fixed, he said.

“For the vast majority of devices, repair is the right choice,” said Affelt, adding that the exception might be old, inefficient refrigerators that can contain powerful greenhouse gases which fuel climate change.

Next on the EU Agenda

Next on the EU agenda: implementing a right to repair for consumer electronics, including computers, laptops, and smartphones, major sources of eWaste.

Some EU states have gone farther than the wider bloc as in implementing right to repair provisions. France, for example, from this year forward will require manufacturers to include repairability scores in information provided to consumers; these would assess how easy it is to repair a product up front, for consumers to considerwhen making purchasing decisions, according to Tech Republic:

Apple introduced these scores to its online stores in France on Monday. Manufacturers have until the end of 2021 to introduce these grades to their products before they risk facing legal sanctions.

And Tech Explore reports that Sweden ‘’nudges’ consumers to chose repair over replacement by levying lower value added taxes on repair services and parts than on new products.

That’s the same Apple, by the way, that’s long been the right to repair movement’s Antichrist, resisting implementing any right to repair, relying on far-fetched arguments, including the whopper that allowing repairability would endanger consumers. In its maneuvers, Apple ]fights against the interests of its customers and the environment, which would benefit from relatively lower-cost repair over replacement.

In response to years of consumer pressure, Apple has now made some limited right to repair concessions, announcing last year that it would make spare parts available to third party services that repair Mac Computers, according to Tech Explore.

What Does EU Policy Bide for the U.S.?

So, now that the EU is committed to trodding the right to repair path – with the Gallic extension – how about consumers on the western side of the pond, e.g, the good ‘ole USA? Birthplace of planned obsolescence. Which lags badly behind many other countries, especially the EU but also parts of Asia and Latin America in its waste management policies.

When will USians see similar right to repair provisions enacted? (see Will 2021 Be the Year for the Right to Repair? and Right to Repair: Saves Consumers Money, Promotes Local Jobs Rather than Global Supply Chains).

Alas, not imminently. Although many states have teed up right to repair legislation, all U.S. states – including California, Massachusetts, and New York – have yet to enact any state legislation, lag the EU, with the exception of the successful November 2020 Massachusetts ballot initiative to provide third parties access to automatic telematics information that dealers and automakers had kept to themselves. This November 2020 initiative built upon an earlier 2013 right to repair the Commonwealth of Massachusetts acted for automobiles (see Right to Repair Redux: Massachusetts Ballot Questions).

In fact, the most visible recent right to repair move was for a market leader to renege on a prior commitment. In 2018, John Deere and other agricultural equipment manufacturers loudly promised to make right to repair information and diagnostic software available for its tractors and other sophisticated farm equipment, so as to forestall right to repair legislation then pending in several states.

According to a February 19, 2021 press release issued by the U.S. Public Interest Research Group (U.S. PIRG):

For years, farmers have been calling for access to the tools needed to repair modern tractors, combines and other farm equipment. Their efforts resulted in dozens of Right to Repair bills — legislation that would require manufacturers to give access to their repair materials to customers and independent repair shops.

Responding to that pressure in 2018, trade associations representing the dealers and manufacturers of agricultural equipment — the Association of Equipment Manufacturers (AEM) and the Equipment Dealers Association (EDA) — debuted a new industry promise (PDF) to create and sell (or lease) new tools to allow farmers to repair their own equipment. These trade associations pledged that the tools would be available for equipment sold on or after January 2021.

But 7 weeks into 2021, these tools are not for sale on JohnDeere.com, and we’d heard reports from farmers across the country their local dealers didn’t have those promised tools available. To investigate, U.S. PIRG Right to Repair Advocate Kevin O’Reilly called 12 John Deere dealerships in 6 different states. Of those, 11 told Kevin that they don’t sell diagnostic software and one gave him the email address of someone to ask for the tools — though after two days, Kevin had not heard back.

Vice ran an excellent article on John Deere’s failure to follow through on the way 2018 pledge. This article pulled no punches, as the headline suggests: John Deere Promised Farmers It Would Make Tractors Easy to Repair. It Lied. It’s well-researched and thorough and I encourage interested readers to read it in full. As the article discusses, Vice independently contacted John Deere to attempt to get access to the software and repair information U.S. PIRG had also sought- also to no avail.

U.S. PIRG also produced a report on how dependent modern farm equipment is on software, which makes clear how much of a problem John Deere’s policy poses for farmers and – the costs it imposes:

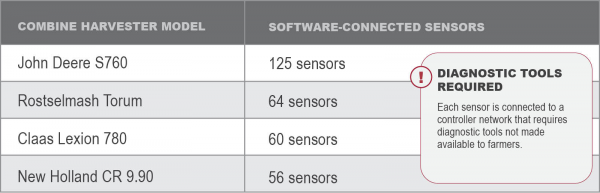

The lack of software repair tools is a huge barrier for farmers, according to a new U.S. PIRG Education Fund report Deere in the Headlights. The report provides background information about why John Deere and its competitors’ tractors are so hard to fix. Modern farm equipment, like most 21st century technology, runs on software. Our research found as many as 125 software-connected sensors in a single combine harvester. If any of those sensors go down, software diagnostic tools are needed to repair the combine and put it back into use.

But when manufacturers restrict access to the software tools needed to repair broken tractors, farmers need to rely on dealerships and a simple task can turn into a month-long wait.

For example, when a tractor belonging to Walter Schweitzer, a third-generation farmer and President of the Montana Farmers Union, broke down, he was forced to take it to the dealer instead of buying $500 in parts and fixing it on his own. A $5,000 repair bill later, he was able to get back to work—but a month behind on the typically tight farming schedule of plowing, planting and harvesting.

“Farmers, we’re an independent bunch. When we see a problem, we’re used to fixing it,” Schweitzer said. “But without the software we need to repair our equipment, we’re serfs. We deserve the freedom to fix our own stuff.”

John Deere or Jean Cerf?

Interestingly, the right to repair software John Deere is failing to make accessible to U.S. farmers – contrary to its 2018 promise – is widely available to its European customers. As Vice reports:

It would not be difficult for John Deere and other manufacturers to comply with a right to repair law, or, at the very least, to abide by its own promise. Europe has had some right to repair regulations which require “standardized access to repair and maintenance information (RMI) systems to provide repair and maintenance information for vehicles used in agriculture and forestry” since 2013, and manufacturers comply with those.

EU farmers and now consumers have access to right to repair information, as EU policymakers have enacted laws that require manufacturers to provide the information. The John Deer example demonstrates that U.S. lawmakers cannot rely on mere company promises and goodwill alone. As per Vice again:

And so the solution in the United States seems like it’s going to have to be the same. Not a promise from manufacturers and dealers, but legislation with the force of law.

As Nathan Proctor, U.S. PIRG’s Right to Repair campaign director, emailed me in response to come questions, “If you can get these tools in Europe but not in the states, that puts our farmers at a competitive disadvantage — and adds insult to injury.”

And Nathan’s final zinger on John Deere’s business practices: “Are they selling digital repair tools to French farmers, but not a farmer in Nebraska? Perhaps they should rename themselves to ‘Jean Cerf’.”

I can’t help but wonder if perhaps it should be enough for the company to provide 3D models for parts, if they don’t want to warehouse parts for a decade. 3D printers are a thing, and might better serve this small market, for a lot of it.

Also, the advent of electric farm machinery may result in a gross simplification of these tools and improved reliability.

That’s an extremely techno-utopian viewpoint. The parts that fail on machinery are complex objects like solenoids and hydraulic components, composed of dozens of different materials and formed with precision by several classes of machine tools. Until a 3D printer is invented that can manipulate and form on the molecular and/or crystalline level is invented, they are unprintable. These machinery suppliers already have a sizeable stock of parts on hand for their dealer repairs, and they know how to increase that stock if outside customers gain access to it.

I don’t know about agricultural repair parts specifically, but if it’s like my trade, the cost of the parts easily covers the storage costs.

Consider just the Amazon Kindle e-reader. There is a common situation where the charging jack no longer connects to the plug. The diagnostic is to pinch the device at the entry to the jack. If it charges momentarily, that is the death knell: “The solder holding the jack near the edge of the device has failed.” Somehow, it is not accessible to the amateur owner, and it costs more for a technician to open it and re-solder than the cost of a new Kindle. The question is, why is this not a flaw and responsibility of the manufacturer? How can a perfectly good Kindle reach end of life when the charge cord fails to connect?

Really angry people with some time and money might go ahead and pay to have the kindle fixed in order to withhold ” just-that-much” money from the Big Kindle division of Amazon.

This meshes up perfectly with dingdong Schwab “You will own nothing and be happy.” Phonograph records you bought decades ago are illegal to do vinyl rips of and load onto your iThing. Software is all ‘Cloud’ based with a monthly rental fee. The scheme is easy to see: The usual gatekeepers from back in the day (the oligarchic networks) will control discourse. The lowyly can ‘create content’ so long as it’s approved and not ‘sus’ or ‘problematical’ to the ruling caste (which somehow is now self-identified as ‘liberal’. But TOS dictates you won’t ‘own’ this content. That way the appearance of a spontaneously re-generating youth culture can be maintained. Meanwhile your car will really be owned by the manufacturer, which will require constant fees for ‘firmware updates’ and heaven help you if you try to fix it yourself. Dealer only repairs according to the TOS you agree to when you ‘log in’ to the car’s ‘OS’.

You can see how Larry Ellison’s ‘cloud’ mentality has been taken up with enthusiasm at every conceivable level. The ‘consumer’ will just be a drone in an Orwellian Anthill. The World Without Sin. More likely, this entire scheme will collapse under the weight of its own collossal hubris. Let’s all do our part to monkey wrench it to death. “I wish I was a mole in the ground.”

What can you do about this?

Use consumer reports, free from many libraries, to research all used and new cars. Buy simpler models with fewer screens that control things. Knobs are good! Simpler used cars with a good track record and high reliability index are the most economical when one adds up higher insurance, registration and other costs for new vehicles.

Only use the car dealership for one purpose, to do repairs under warranty, if you buy from them.

Research, locate and patronize a good local garage with competent mechanics. Pay them in cash and negotiate a better price that credit card customers pay.

One does not have to get regular service at the dealer, nor use their parts to maintain a warranty;

https://automotiveaftermarket.org/magnuson-moss/magnuson-moss-warranty-act/

Broken promises? BOYCOTT JOHN DEERE

The John Deere example is particularly worrying in that “access” to software and repair programs is a function of wealth. This directly poses a disadvantage to small and “family” farms.

We all eat what farmers grow. Whittle down the ‘supply’ of farmers to a few mega-farm conglomerates and you end up with the precise conditions that create predatory monopolies and ‘combines’ in the past. Human nature is fairly basic. This progression can be anticipated and predicted.

We live in an age of “Sophisticated Accumulation.”

When you add the food supply to the class war methodology, you usually end up with revolution. Why? Because tightly controlled and concentrated food supplies are easy to disrupt, with or without pre-planning.

Might there be a market for small analog tractors if someone still makes small analog tractors?

There certainly exists such a market but corporatism doesn’t want small organic farms with local mechanics and small towns

See the first chapter of Zephyr Teachout’s Break ‘Em Up, The Chickenization of the American Middle Class: “John Deere is the fifth largest agricultural lender in the country” (p. 26). As such they can do what they damn well please. For now.

Bought a new refrigerator with a 4 year extended warranty, it died on the 5th year from a circuit board issue. Of course, there were no circuit boards available, so had no choice but to toss it. Talked to several neighbors who had the same issue of fridges dying from circuit board failure after 5 years. I can’t help but wonder if the failure is programed in at the factory. My grand parents had their old refrigerator from the mid-50’s in the basement where my grandfather used it as a beer fridge until he died in 2015. To my knowledge it had never even needed so much as a minor service in all those years.

Does that work as a business model? It might get customers back on the market, but not exactly jumping to buy your brand again…

Nostalgia: The Ford Wrench was a multi-purpose tool – a sort of Swiss Army Knife of the rural economy. Ford made it; it was part of the ownership and sustainability of the farmer’s means of production, the tractor. The farmer was a small business owner, and in one person performed staff functions on a small scale: production, maintenance, accounting, hiring, firing, planning, vision and mission. Ford fit into that micro-economy and made an honest profit. Somehow, this post shows a decline in the support of the independent multi-talented class.

I have an older Sonata. Once when I took it to the dealer they pulled out a large mouse nest behind the cabin air filter, so I decided to do the maintenance on that myself. It turns out that getting one’s fingers behind the two levers that give access to the filter is very difficult.

The other day I mentioned my troubles to my local mechanic and he laughed, saying he has hundreds of dollars worth of little tools to fix problems just like mine. Some he has had to make himself.

There’s more going on with John Deere than just the right to repair. The equipment covered by the Digital Millennium Copyright Act (DMCA) is the mostly the large high end machinery used in large scale farming.

This equipment is $100k plus in cost. When I first saw this come up I started checking the farm forums. There is another issue that also appeared in the discussions. This issue was the John Deere had the right to determine the service life of the equipment. In short John Deere had the right to take back the equipment when the service life was expired. Even if you own the equipment. Most farmers sell off the old equipment to buy new (to offset some of the cost). So the farmers never really own the equipment. I haven’t seen if this was resolved. Anyway, there is a trend for all this to show up in the automotive and other industries. I currently have just purchased a new tractor, not a John Deere. My old one is a John Deere (not covered by the DCMA). As an R&D engineer (hardware and software), there is no way I’d ever by another piece of John Deere equipment as a matter of principal. I known farmers that are currently using equipment that’s over seventy years old and stuff still works good.

Thank you Jerri-Lynn! I feel vindicated, sorta. Here is something personal. This goes on, I am convinced on every level, including the medical field. I am stone deaf in my left ear from trauma. Almost 20 years ago, I signed up for a Cochlear Baja hearing processor. (It was analog at the time.) I updated to a digital model several years later. I still use it. It works perfectly, however, it needs a few accessories to function well. Cochlear America would simply not respond when I asked about their discontinuing necessary accessories. However, I found these accessories on a hearing and deafness website in the UK. The note that I received after I placed my order was “Your country’s trade agreements will not allow us to send these to you.” I called Cochlear America and gave them the what for. Their response? “Where did you find this site? You must either upgrade to a new processor or see if accessories are on eBay.” This American woman was astonished that I’d found a site unrelated to Cochlear (Global) that had what I needed. (Duh. Go to eBay??)

Now, the cost of a new processor is from 5-7k. I don’t need or want an upgrade; I just need the accessories so it continues to function! But this is America. Just pitch it if it’s old.

Right to repair is one thing, cost is another.

So I really hope this leads to increased competition on repair jobs!

Practical example: our 8-year old washing machine broke in September. It would have been 150 euros to get a diagnostic on the thing and then another (probably) 150 euros to fix (an electronics part). We decided it was not worth for such an old machine that cost ca. 500 euros and went out and bought a brand new one for about 400 euros. Maybe wasteful, but the more these things are full of electronics, the more will break. Still, in my experience it is right after the guarantee ends, so I should be grateful for the extra 6 years!