By Lambert Strether of Corrente.

If you’ve been listening to Mike Duncan’s Revolutions podcast (“Good Riddance to Dear Nicky“) you know that one of the causes of Imperial gridlock — the inability of Czarist Russia to mobilize for whatever purpose, no matter the laws passed or reforms made — was sheer incompetence; people placed in positions of authority, whether high or low, who had no idea of getting the job done (whether through cronyism, corruption, ineptitude, institutional pettifoggery, or sheer bloody-minded indifference). So you will see why the Romanovs immediately sprang to my mind when I started looking into the container crisis at the Ports of Los Angeles and Long Beach, hereafter “the Port.” (The container crisis is one part of a larger crisis in the supply chain generally, which is out of scope for this post, and a good thing, too, because it’s enormous and not immediately tractable.)

The proximate cause of my disgruntlement was a Twitter thread from Ryan Petersen that Yves posted, upon which I am about to expand. The only people I read who seemed to have a handle on the Port situation, or the supply chain generally, were logistics specialists — Petersen is CEO of a logistics firm — or truckers on the Twitter. Everybody else, and especially the press, just seemed to be hand-waving. (Dashboards, anyone?) I’m going to be using images, because sometimes I need to quote and highlight several tweets at the same time.

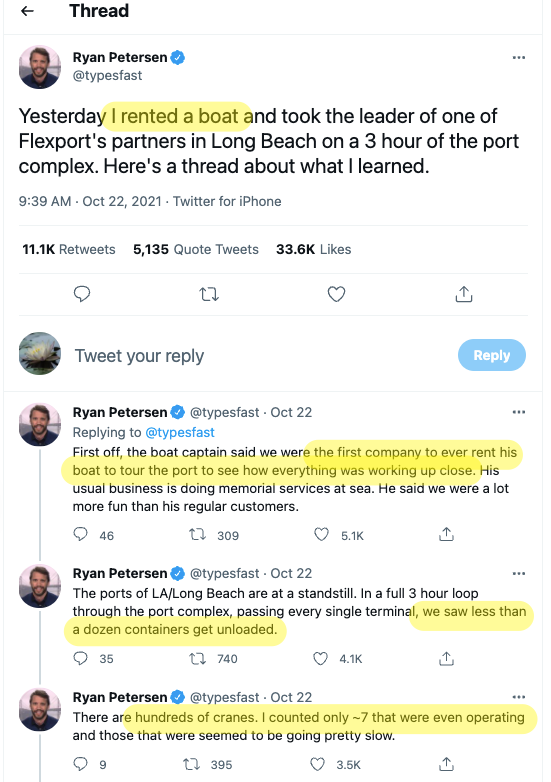

Petersen begins:

There are (as of today) 76 ships waiting at the Port, with 430,000 container cargoes worth $26 billion. So you can see that moving a dozen containers and operating seven cranes won’t be putting a dent in that any time soon. I had no idea things where this ridiculously bad, and I do try to keep track.

But I had already started grinding my teeth with the first two tweets: Where was everybody? Why was Petersen “the first company” to go down to the Port and actually look at what was happening? The crisis at the port has been going on since at least August. Did no news-gathering organization think to write a story? The Los Angeles Times? The New York Times?

You’d think the clogged Port would be a wonderful photo op, especially for a publicity-hungry McKinsey Consultant. Leaving the (Democratic) Los Angeles City Council, the (Democratic) Los Angeles Mayor, the (Democratic) California governor, and the (Democratic) California Congressional delegation aside, where was the Secretary of Transportation? On paternity leave, that’s where, since August, and then doubling down on it. Otherwise, “lying low,” as Politico puts it.

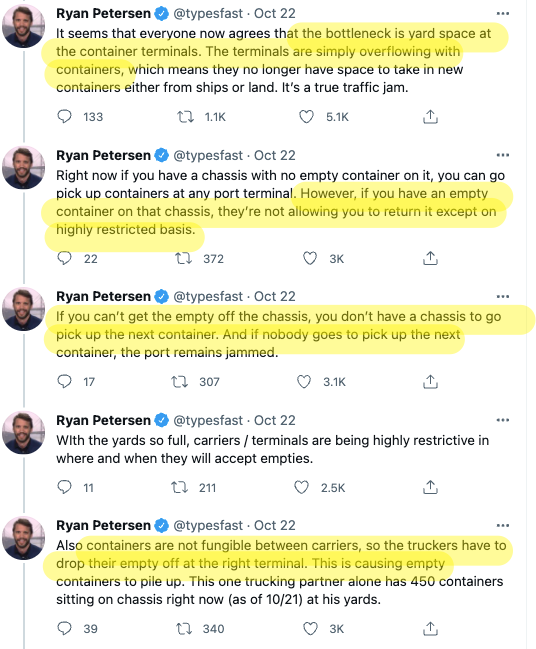

The beauty of containers is that they are as modular as Legos. But that beauty comes at a cost: Containers have no wheels. So, what the cranes should be doing is moving containers from ships to trucks, which do have wheels, on which they drive away, bearing the container. The truck bed onto which the crane placed the container is called a chassis. It should be simple and clean, but there are problems. Petersen again:

Note that one of the key blockages is a business requirement: Containers are “not fungible.” They must be dropped off at the same place they are picked up. (Note that railroads don’t have this business requirement at all; that’s why you see a BNSF engine pulling (say) CSX cars, and billing for them. BNSF can settle up with CSX later because railroads can track their cars. I don’t know what the Ports problem is.

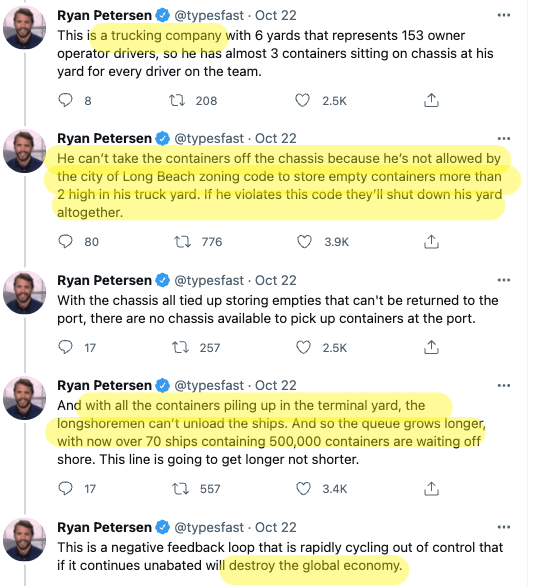

Goods having been delivered, the containers, on their chassis, are returned by truck to the Port, empty. But there’s no place to put the container. So the truck waits at the trucking company. Peterson again:

(I think “destroy the global economy” is harsh; the supply chain has more problems than the container crisis at the Port).

Here at last we have a ray of hope. As alert reader Flora points out:

One of his ideas gets a quick response from the mayor of LB.

As we see:

Update: The city of LB just announced it has temporarily suspended container stacking limitations.

Thank you everybody who called the governor and the mayor to request. They got the message, you can stop now… https://t.co/jp3S07NS4l

— Ryan Petersen (@typesfast) October 22, 2021

Again I ask: Where was everybody? Why on earth did it take a Tweet storm — @jack, hat tip, you’ve singlehandedly done more good than Zuckerberg has ever done — to get this small thing done? Why did the Mayor’s office not think of this? Did nobody ever look out the window? Why did the trucking company not get the Mayor’s attention? If they got the cold shoulder, this is trucking. Couldn’t they have escalated?

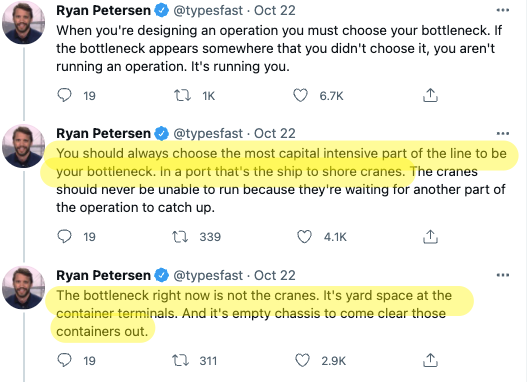

Having identified the key problems — and I’m assuming that the container bottleneck is the only problem at the Port — Petersen turns to solutions:

I like this argument. In a past life, I used to buy printing, and so I would visit printing plants. You never want to see empty bottles tossed under the workbenches. But the key sense is not sound but hearing: You want to hear the press running as soon as you open the door. If the press is not running, that tells you the firm isn’t managing their most expensive item of fixed capital up to capacity (or it’s broken, which is worse).

Petersen’s first step towards a solution was actually adopted, as Flora has shown, the Romanov bureaucracy having acted once someone, anyone, gave them some guidance. Here is Petersen’s second step:

This I’m not so sure of, partly because I’m not sure how easy it would be to wrest containers from the hands of the military, but mostly because I’d like to see numbers. All of the coverage is marked by a paucity of numbers, except for the containers piled up at the Port. (That’s also why I reacted so strongly to the two numbers Petersen proferred in his original tweets: a dozen containers, seven cranes.) Petersen’s next step:

Presumably, there aren’t any railheads near Redwood forests; or, to be more bureaucratic, a President is not a CEO. There’s a lot of site selection to do, and permitting that would need to be waived, to get this done. Even assuming everything is maximally expedited, we’d be looking at months not weeks let alone days. And that’s assuming we’re not dealing with the Romanovs. Petersen’s penultimate step:

Lol, the railroads love them their “1500 mile train journeys to Dallas,” because that’s the highest margin business they have. (I believe this is called “precision railroading.” No stops, no switching, no dealing with tiresome businesses along the way.) So the idea of railroad management howling is almost enough to sell me on the idea. My hesitation comes because the railroads, like everything else, are highly optimized. They don’t have any slack either. So when their capacity is diverted to this laudable new purpose, what gets sacrificed? (I suppose the argument is that nothing does, since the ports that the railroads unload at are blocked; but I’d like to see that proved, and I’d like to know the effect on other ports that are not blocked as the Port is.)

And finally:

Here again I want numbers. How much capacity does the West Coast (and, I suppose, Mexico’s West Coast) have to absorb this shipping? And how many of these barges and small container ships are there?

Again, however, WHERE IS EVERYBODY? Though I’ve tried to poke holes in it, the solution is simple and clean: You have a capacity problem. Get more capacity! Petersen at least proffers a worked-solution that was intuitively obvious enough for the Mayor of Long Beach to act on it. Who else is doing this? Governor Newsom? Buttigieg? The task force Biden set up, pointedly nominating neither his Secretary of Transportation nor [genuflects] his putative successor? Bueller? Bueller? Bueller?

Back to the chassis. If I have one nagging feeling about Petersen’s approach, it’s that he thinks he’s looking at a technical problem, when in fact he’s looking at a business problem. From a less spectacular thread than Petersen’s, but one well worth a read:

Why haven't pool owners (who are often terminal operators) fixed this? They have no incentives to.

Containers don't get moved? They get storage fees.

Drivers miss their terminal appointments? More fees.

Tracking chassis between pools? Sounds like effort. So untidy!

13/15

— Christopher Smith (@chrylis) October 20, 2021

There are Romanov lackeys who are very happy to be collecting rents with things just as they are. Perhaps our Stolypin, whoever they may be, can get round all that. Perhaps not. But clearly, it’s Romanovs all the way down.

Peterson’s line about making the bottleneck at the most capital intensive part of the process (which means that that you have surplus capacity everywhere else, where that capacity is cheaper than at the bottleneck) is elementary “theory of constraints”, something that I think must have been taught in business management in US decades ago.

While this anecdotal analysis is interesting, it is insufficient. The question that arises for me is why are empty containers stacking up? Why don’t we force China to ship them back to China where they could be refilled? Yes, there likely are management rules getting in the way at the port, but, dear me, Secretary Buttigieg, hire a top-drawer management consultant to define the problems and identify solutions. No, we don’t expect you to cut short your paternity leave, but we do expect you to put someone in charge who can get the job done.

Look up why we have “Canola” oil, at all. Originally created (largely) to fill containers.

If we did make China pay for it, somehow, there would be a lot less incentive to stock holiday shelves with cheap crap.

The single-use container issue writ large. Why concern yourself with paying for recycling or disposal when you can dump that off on someone else?

Don’t assume that the empties are backed up in the port container yards where cranes can get to them. They might be miles away from the waterfront. Also, are empties needed at U.S. shippers for export cargoes?–get them there. As stated, empties need to go to the correct terminal on the correct days of the week to get on the correct ships. Not all go to China.

This article only looks at the highly visible part of the tangled supply chain. Do rail lines have more container stack cars to haul containers and do long haul truckers have capability to carry more containers on the highways? Are the container terminal gates open enough hours of every day? Do warehouses across the country have shelf space for more goods?

Agreed, we need to dig into the whole mess, not just one part. We need someone to take charge, but in a useful way. There is more than one knot in this badly tangled chain.

It’s still taught. Education isn’t the problem, it’s a lack of government leadership and an overarching industrial policy which guides the markets toward more optimal equilibria.

The description of the Romanovs also matches the lazy,fearful and vindictive SNP at Holyrood and Westminster.

Jailing Journalists, malicious prosecutions, risible, doomed to fail policy (what there is of it) and legislative incompetence.

cant forget the Tories either. they do the same things

Here’s another question: Why didn’t the management of the shipyard, whose job it is to move freight between ships and other modes (truck or rail) do this analysis? And after they got their analysis done, call the mayor, or the gov’nor, or the President to tell them what needed to get done?

The other question I have is this: “Did that analysis get done, and the results quietly shelved or overlooked?”

If I was interested in applying pressure on China, and I didn’t want to overtly re-commence a trade war, I’d slow-walk those containers off those ships.

It’s really expensive all the way back up the supply chain from U.S. port back to Chinese factory to have all those ships sitting along Long Beach waiting to get unloaded. And it doesn’t just monkey-hammer the China-US trade, it affects all other China-outbound trade because ships and containers are bottled up at Long Beach.

Here’s another question: Why aren’t ships being re-routed to San Francisco, or Portland, or Seattle or Prince Rupert to unload? Can’t those ports move traffic?

That’s what makes me wonder if this isn’t deliberate, somehow. There’s just too many other ways to move that freight, and the other ways don’t seem to be happening.

I have heard that some ships have been re-routed closer to Yves’ neck of the woods on the Gulf Coast, although I believe for the moment that’s just the Atlantic freighters avoiding the East Coast; don’t think the West Coast ships have gotten desperate enough to go down through the Panama Canal, and even if they were to I suspect we’d see a new bottleneck form there.

Many of the cargo ships waiting to enter the Port of LA are Chinamax-size ships that don’t fit through the Panama Canal. Chinamax ships have a 65m beam (width) while even the new locks on the Canal are only capable of ~50m beam.

Agreed re Chinamax beam width issue.

But why not Oakland? They are supposed to be begging for business. See: https://sanfrancisco.cbslocal.com/2021/10/19/supply-chain-issues-port-of-oakland-officials-issue-plea-for-more-cargo-ships-to-unload/

I believe our Charleston has a container facility. Savannah as well. Of course it’s a lot of bunker oil between here and the West Coast but someone has already more or less made the suggestion.

http://www.maritime-executive.com/index.php/article/gov-ron-desantis-calls-on-ocean-carriers-to-divert-ships-to-florida

could reroute to Vancouver Canada. i think they also have a large port. problem is they may also have the same problem

I truly hope that we are seeing idiocy at work and not some backhanded attempt at pressuring China via slow-walking imports…as the US has to rely on China for nearly everything even for glass food containers!

See sparser stock of your favorite tomato sauce at the store? Blame all the empty glass jars sitting off of Long Bech waiting for disembarkment

hm…been a whole since i saw tomato sauce in class jars, that easier to make in the US, and there would be less damage to the product too. but then you wouldnt be using shipping containers

part of our problem is that we consumers changed our spending patterns in since 2020. before it was just about any thing that people would buy. now its more like what do we need to have to work from home, dont go any where unless you have too (no entertainment or restaurant spending), now we eat at home, and use Netflix or others. and it wasnt that long ago, that transportation companies were worried (and complaining about the lack of new truckers…who knew that treating them badly would lead to fewer truckers…and fewer replacements for those that retire….some times years early than they had planned to do so). seems that the same problem that restaurants and manufacturing and others have too. who knew treating workers badly, that many wouldnt come back

I broke the lid on my butter dish. I am a bit disabled so Ive been buying things like that from wal-mart delivery. I found that A good glass single stick butter dish can be expensive, about 12 to 18 bucks for a pyrex. I am on a limited income and looking for a deal so I”m on the Internet looking at butter dishes (think about that).

First try: Set of two clear single butter dishes, $7.99, free shipping over $50, nice as I had some other things to get. Well they are made out of plastic, barely heavier than take out food plastic and it never seems to be clean. I love butter so clearly these won’t do.

Second try: Single crock butter dish, $4.99. Sounds and looks good so I put it on my next order. Upon delivery everything looks great: its heavy, a simple square design, a heavy crock type material, … in fact it looks like a miniature mausoleum (which is what I call it) . You cannot see from a casual glance what the butter situation is.

Mournfully realizing that my quest must continue I started to think about shipping containers full of butter dishes from China: heavy crock butter dishes delivered to my door from half world away for five dollars. Nothing against the Chinese, my admiration grows the more I read about them, but the size of the logistics is astounding.

Apparently butter dishes are kind of an heirloom thing. Ive seen them for $40 to over a $100, Amazing to a single bachelor. Ill drop $20 next time.

Made in USA $5.99 currently says “in stock”

https://www.containerstore.com/s/kitchen/food-storage/anchor-hocking-glass-butter-dish/12d?productId=10006307

(I welcome the challenge of trying to find stuff made in USA!)

Thank you, that is exactly the same one I had!

To get even more granular about butter dishes, I discovered this model works best when turned upside down from how it is pictured. The curved lid (as pictured) with such a shallow base where all the butter gets pushed to the edges, which is where the lid rests makes for a grease on glass situation; not good for clumsy people like me. So I used mine upside down, the lid was easy to grab and the butter has something to push against. I will get this one.

Thanks for the link. Who’da thought? Yes, I have one! It worked perfectly to protect the butter from the cat, who was horrified when he found himself himself licking glass. Anyone recall when much of the glass besides Pyrex was French Arcoroc, which is still available? I have scads of glass storage jars. Most are made in Italy and France but I admit they’re very old. For glassware and cookware not made in China try food52.

And thanks for this, Lambert. This is a cluster you know what of Romanov proportions.

https://food52.com/

We have a stainless steel butter dish — not much to look at, and you have to remove the lid to see how much butter is in it, but it’s never going to break. An heirloom piece, I suppose.

An alternative to a butter dish which we used after ours was broken — a small plate with a heavy drinking glass upside down to cover the butter. Doesn’t fit a whole stick but will fit half of one and doesn’t need refrigeration except in the very hottest weather.

What is the point of pressuring China when the real beneficiaries of all this international freight are Walmart, Amazon, Apple, etc…? based on what I have been reading in various media accounts US retail are the most desperate for these ships to be unloaded. China? Not nearly as much.

There was a time before Free Trade when Americans made all of America’s glass jars. Because of Free Trade, glass jars from overseas could underprice American glass jars no matter how low the price was dropped on American glass jars. So the glass jar industry was moved overseas.

And as long as we have Free Trade, it will never “pay” to try making a glass jar in America. If we want to be able to make glass jars in America again, we will have to abolish and cancel every Free Trade Agreement we have so that we may “legally” re-protectionise our own political-economic society and allow Americans to rebuild and regrow a made-in-America glass jar industry.

I doubt the International Free Trade Conspirators would deliberately pressure China by “creating” a shortage of back-tracking empty containers or bottlenecking the offloading of full ones. They would not want to risk these supply shortages or absences lasting long enough to torture tens of millions of Americans into deciding they would rather pay more to have something than pay less to have nothing. Because if tens of Americans reach that state of mind, they might try torturing the Free Trade Occupation Government into re-protectionising America for at least those things they would rather count on having, even at the cost of paying more for them. And if the “Fair Trade” camel is allowed to get its nose into America’s economic tent, pretty soon it will try getting its whole hump inside the tent as well.

And the Free Trade Conspirators don’t want to risk that. So it would take an extreme amount of torture and terror to terrorise and torture the government into permitting Protectionism even for “essential” sectors and supplies.

Containers can be tracked — some info:

https://www.airfinder.com/blog/shipping-container-tracking

The “management of the shipyard”? The highest managers are the port commissioners: https://polb.com/commission for Long Beach. Mayoral appointees (Romanovs!) all. One longshoremen’s union rep, scant experience overall in transportation let alone freight management.

well some of this is a business problem, they had so much set up for just in time, that any hitches (lack of truckers for example) means that there are more and more blockages to the point that stuff just cant get off the ships. had they decided long ago to maybe diversify how goods left the port, but that wasnt done, since business would have had to pay for that. they chose not to. while we have a real shortage of truckers to go along with it, most chose to retire, mainly cause of how they were treated, and new one dont care to join the ranks…cause they have seen how that were treated. another example of shortermism come home to roost?

Huh? Did you read the post? This comment comes off as a violation of site Policies (requirement to read a post in full before commenting).

The point of containers is standardization. The problem is the business choice not to treat them as fungible, as Lambert explained (his comparison to railroad cars).

Seattle/Tacoma is roughly at capacity according to the local paper. Don’t see any loitering container ships out the window.

Check this map: the north/south inlet is Holmes Harbor on Whidbey. Any dots there are container ships. Right now there are three (may have changed by the time you see this) but there are usually four. HH is lined east and west with high-end (some multi-million-dollar) homes. These ships are waiting to be able to unload at the Port of Seattle. There are often a couple of ships off Everett too.

No spare port capacity here in the PNW.

Also, some container ships are slow-steaming offshore waiting for an anchorage in the Puget Sound area. There are no large capacity west coast container terminals running under capacity. The ship owners would divert their ships in a minute if they could improve operations. If diverted, not only getting the containers transported away from the terminals is a concern, train & truck capacity, but also getting loads and empties destined for Asia to these terminals for loading is necessary.

And even farther West in Port Angeles. When I lived there 5 years ago before this shipping crunch there were sometimes 5 or 6 ships anchored Round the harbor waiting for permission to enter Seattle.

Jokerstein & Rainlover

Similar to the situation here on the south BC coast and Vancouver Island. Ships bound for Vancouver “stacked” in the Gulf Islands channels or in the Salish Sea off Vancouver Island, Container ships waiting to unload, bulk carriers waiting to load. Occasional complaints from people living along the shores of the lights and noise from the anchored ships.

Here’s a perspective from the Longshoremen.

https://www.seattletimes.com/opinion/dockworkers-are-available-24-7-others-in-supply-chain-should-be-too/

I’m not sure of all the logistics in the channel here but at least from my dilatant knowledge level, it’s not only the port storage yards that are jammed full but also the railroad shipping hubs, located in the central US, where the east/west containers/railroad cars are routed to their final destination. This has happened several times in the last decade and was the cause of several other, granted less dramatic, supply chain delays.

With regards to finding alternate storage locations, there are several major Military bases in the region that have both space and are served by major highways and rail lines with the goal of being able to rapidly deploy tanks and troops overseas. No idea if there is storage space available (the military has their own stuff) or if there still exist the ability/support infrastructure to handle things at this level but this is something that at least can be commanded at the national/state level (yeah yeah I know that I would not count on the military bureaucracy of being able to do anything but light cash on fire) so you could at least avoid the local permitting process.

In summary, If the trains being backed up is a substantial part of the problem re-routing to Oakland or San Diego might get the cargo off the ships, but it does not move the freight much further down the line. If storage space is the prime issue, there is existing US government property with rail access in both the LA (29 Palms is more than 100 mi but has rail and highway access), SD (I don’t know the rail lines but there are at least 3 major bases within 25 miles of the port), and SF regions which may be available for temporary use (the retired Alameda air station is directly adjacent to the port of Oakland for example).

I suspect that there are major issues with switching/loading/moving this amount of re-routed cargo (lord forbid we invest in surge capacity – see Covid related medical supplies) but it’s not completely out of scale to think that the feds/state could do something here.

Forget San Diego. Very small commercial port and only a single rail line to LA area. Never was nor never will be a commercial port.

> It’s really expensive all the way back up the supply chain from U.S. port back to Chinese factory to have all those ships sitting along Long Beach waiting to get unloaded.

I wonder if the goods that are backed up were paid for with letters of credit that don’t pay the seller until the goods are landed. That could cause a cash crunch at enterprises that are probably operating on very thin margins.

Yes, that’s a very common approach. Good point.

And yes, Chinese producers are already stretched. Many already use supply chain financing.

I don’t think anyone is trying to Problem Solve the problem, or maybe even cares.

I live near the Port of Seattle, and I can see the container ships docked by Blake Island. Yet, the port seems only kinda busy. I hear there are over a dozen ships waiting now.

If you go to the NorthWest Seaport Alliance website (https://www.nwseaportalliance.com/cargo-operations/terminals), you can see there are multiple terminals that simply are not being used. Terminal 46 is empty and for lease. Terminal 5 is empty and supposedly being modernized. In Tacoma, the East Sitcum Terminal is also for lease.

Maybe Terminal 5 is down because the West Seattle bridge failed…. but it has a rail spur and it’s own railroad bridge. Who knows why it’s just a big empty parking lot.

It’s makes no sense, it’s all a mystery to me.

With all the data flying around the country, something like this remains unorganized. All of this appears to catch “the economy” by surprise…and all you ever hear about is the economic data that’s been collected.

That just goes to prove that the grand majority of data collection is about surveillance.

Update: I drove by Terminal 46, and it’s stacked with containers. Apparently it’s being used as storage.

Terminal 5 is empty because the dock has been shored and repaired for the larger cranes they just installed to be able to unload the largest cargo ships. ETA on opening is in Jan, which should increase the capacity of the West Coast since it can unload directly to rail: https://www.nwseaportalliance.com/about-us/planning/terminal-5-improvements

Santa Barbara was a “small shipping port” through the 1900’s, but now just handles expensive small craft sailing and power boats. Tourists are its main cargo now.

The LATimes has, in fact, been covering the shipping fiasco:

https://www.latimes.com/business/story/2021-10-13/everything-you-should-know-about-the-supply-chain-nightmare-at-the-l-a-ports

I don’t recall reading that port stacking ordinace was causing the backup, though. The Times indicates it’s several issues combined: port space; available truck drivers; etc. Drivers are dropping empty containers on the streets outside their delivery destination so they will be allowed to enter the port with an empty chasis.

This is not to say there aren’t Romanov’s asleep at the wheel in this supply chain disaster.

Soon enough they will be mooring detained cargo ships off the Santa Barbara shoreline. Then hell will be paid by the Politico’s.

(I’m affected by all this supply-chain nonsense; I can’t get a motor mount for my vintage VW Bus!)

Santa Barbara shoreline? I saw a recent video that showed “parked” container cargo ships lined up off of the shoreline at Huntington Beach. They weren’t close in, but they were clearly visible, the entire hull, not just the superstructure. That isn’t a ‘cheap rent’ district by any stretch of the imagination.

I’m wondering if the “real” bottleneck here isn’t perhaps the “cost per unit,” wholesale cost plus shipping, at the retail outlet. No one wants their cargo diverted because of the extra shipping charges possible.

Any idea how they achieve this? Normally it would require a crane or giant forklift.

My guess? A chain and a fire hydrant.

And how are they lifted back on a chassis?

That’s “Somebody Else’s Problem” methinks, expecially if the drivers or their companies are paid on delivery and don’t have any explicit requirements to bring back the empty container.

This sounds like a mess, and one that won’t be solved quickly unless the ports incentives are realigned soon.

The storm hit the Pacific NW this week too.

I’m sure that’s causing additional havoc.

So much work to do…so little willingness to pay for it to be done.

Can Americans go a single Christmas without overspending on consumer goods?

Those that must partcipate should go with gift cards…spreads out the demand more. Everyone doesn’t use those at the same time like everyone going to buy gifts at the same time of the year.

Give a check/cash – gift cards are almost as bad as giving someone something they don’t want. Redemption rate is around 80% – you can at least stuff the cash under your mattress for future use.

Or give the cash. Cash will be used – even if it’s a gift for someone who decides to save.

The demand has to be spread out. Do half gift cards / half gifts (based on what is known about the recepient)…anything…but it’s not going to be business as usual and no one is trying anything else.

Also, other things besides shopping can be done to celebrate the holidays and give supply chains some recovery time and your pocketbook.

We could just buy stuff made in America instead of elsewhere. Surely, I jest.

There are aggregator websites that list companies that manufacture in the US (do a search for Made in USA). The lists vary as far as being current. Vendors go out of business or switch to doing some or all manufacturing elsewhere. You can do a search for product name + Made in USA but there’s a lot of false positives so you have to work through it. I’ve compiled a list of vendors I like (mostly moderate price range, a few more costly) and have been shopping almost exclusively Made in USA since the mid 00’s. Appliances are a challenge and electronics are impossible of course, but normal everyday stuff – kitchenware, clothing and accessories, home furnishing and decor, gift items, greeting cards – is accessible.

Thanks for the tips.

https://matthewehret.substack.com/p/how-to-crush-a-bankers-dictatorship

How to Crush a Bankers’ Dictatorship: How the Great Reset of 1933 Was Thwarted by FDR

Precisely! I can’t help but think how much better off the country would be if (some of (at least)) the products on the ships and in the containers were made in the US.

I’m giving N95 respirators this year. I like the 3M Aura 9200 series; they seem to fit snugly to one’s face without a lot of fiddling to get a good seal. There are two elastic (9210) or rubber (9205) bands around the back of the head/neck. It’s snug but not uncomfortable, and seems reasonably easy to breathe through.

This vendor (not sure if they sell to retail purchasers) really likes this respirator:

https://www.youtube.com/watch?v=ai5cpLZufSI

I bought a super duper respirator, the kind that makes me look like a terrorist planing to deploy a chemical weapon.

Problem is it has a valve, so great for me, not for anyone else. No can use on planes even before you get to passenger freakout factor.

Would you happen to know the brand name? (I doubt the same place delivers to me here in Sweden)

*biological

but these days, it’s suicide or bust. no self-respecting terrorist wears a mask.

see what I did there.

I read this thread with interest a day or two ago, probably linked to here at NC.

This country has basically turned into a McMansion built on a rotting foundation.

Maybe they should consult with FB and google about how to best track containers, I’m sure some of their best worst people have ideas.

Huntsman has been on top of the supply chain crisis since the pandemic has started. From following him on Twitter he has been meeting with government officials to try and clear up this mess only to see his plans get swallowed up by government bureaucracy. First the Trump administration dithered and did nothing followed by the adults in the room of the Biden administration.

Finally Huntsman created a detailed outline of concrete steps that can be done to alleviate the port congestion which seems to be the source of Ryan Petersen’s ideas. Whether his ideas actually get implemented remains to be seen but this seems to be the only plan I have actually seen.

some good idea, some not so much. there is a reason that there are weight limits for bridges, ignoring those might end up those bridges collapsing, leading to longer trips to get anywhere if you can (maynot have the worst traffic in the US any more….but break some of the bridges and you fix that). a few others might be how do we get the the empty containers to a collection point, and then back to sea. one way would be take one of the ports and use it to collect all of the empty’s (and who will pay for that?) and ship them back to China (or where ever they came from….its not just China). and who will pay for the NG or military to get involved in what is a business problem? and how long will they be involved? and i suppose some lessening of traffic enforcement rules,,,,but only if that is safe….we dont want to see a huge truck break a bridge. Leading to a few deaths…. do we? …and while its been a long time since i was in SOCAL, its probably true today that gridlock isnt just 18 hours a day, closer to 23-24 hours every day). i suppose another way to help, it get all those who can work from working from all the time. that would take some traffic off the roads, and give companies goals (with penalties) if they dont have %40 or better of their work force who can work from home, working home. while LA/LB may have the worst, or not in the US, suspect all ports have this problem

You know where the interest is? It’s in taking advantage financially of the situation…not fixing it.

Still dealing with brain-dead “the market will correct itself” dogma.

There’s more worry about quantifying the market price of risk and trading on that and other sorts of volatility.

Then saying, “The fundamentals of the economy are strong.”

This!!

Run everything lean as possible, and if there’s chaos, figure out how to make money from that?

Yup. Enron style.

In Mgmt Consultant-speak, it is an Incentives problem, in that the incentives among the various players do not align. If true, one would wonder why we haven’t seen such a break down before.

In my life, this has happened many times on a small scale (“in that the incentives among the various players do not align”) and caused major disruptions to me and others around me. I think it happens all the time.

it does, it just doesnt make the news so much. its a mix of just in time, cost cutting to max, treat workers badly, throw in that said workers decide its better to retire than work., then we have those who dont care, unless they cant make money of it

This is a fine time for inland cities and other population centers at the faraway delivery end of global supply chains to begin creating their own local focus supply circles for brute survival goods at the very least. Even doing that would take years to evolve into existence if they started right now.

Maybe the supply-chain freezeup will get bad enough to torture the people of the inland population centers to think about evolving and designing a City-State supply-circle way of life. Two, three, many supply-circle City-States.

Well, the various states and cities use to have local manufacturers and supply chains until it was wall shipped overseas. Two centuries of effort gone in two generations. What is to prevent another horde of

locustsinvestors from strip mining the rebuilt industries and destroying several more generations of Americans?We need to fire the entire ruling elites and their servants, the elected officials, the political nomenklatura who work for both, and all of the above’s apparatchiks; only then can we be serious about recreating local industries and supply chains

yes…even if the US built up manufacturing so it could more of it for itself, who would pay for that, and what happens when the crisis passes? the ‘investors’ will sell them off…again…caching! and we would be back where we are today, only worse. problem is that our business elite leaders dont care (no matter how much they say differently!). its the mighty uncaring market that drives all of this.

If Free Trade were abolished and America reclaimed the right to exclude alien production by any means necessary and convenient, then it would be safe to invest in made-in-America again because we would have a government we could use to forbid alien undercutting so that no investor in alien undercutting could make any money anyway.

Abolish Free Trade and then many things become possible again.

I am surprised U Boats i.e. Uber for Boats have not made an appearance yet.

I’ve actually met this Ryan Peterson guy once. One time he was trying to recruit engineers by organizing a trip on a boat that took all of us to the Port of Oakland.

Oh my. You remind me of one of my favourite Uber themed start-ups. A crowdsourced, independent Sado-Masochist ‘Dating’ App: “Uber Beats.”

With optional headphones to modulate that auditory visual balance for maximum pleasure? Advanced option with virtual reality goggles?

The mind reels. lol

Why can’t Elon open his tunnel and save the world? Run that tunnel right under the ships.

As testament to the thorniness of implementing freight transportation ‘solutions,’ Ryan Peterson is a smart businessman with sound ideas but to the best of my knowledge his process-automation firm Flexport has not managed a profit over its 8 years and $4.2b raised. Many similar firms already have perished on the hill on which Flexport is still fighting. Competitors and factional fiefdoms (e.g. terminal operators) are pervasive. All in all a tricky business that is indeed too much for Romanovs to manage. Great post.

I’m so glad you said it first. Every bought gift has a carbon footprint. A no-real-pain way to cut carbon emissions (and we had to be cutting them 7.6% per year this year to still dream of 1.5 degrees C). One little contribution could be a no-gift Christmas. It’s mostly mutually obligatory “giving” anyway.

And it might be first step to breaking an addiction for some people.

No coal in the stocking for kids. Instead, spend some time with them, and don’t answer the phone. Read, toss a ball, take a hike, rather than help them boot up the new Oculus Quest headset, then go off to do your own indulgent thing.

Geez, whatever happened to making gifts? I am old, but not that old. It was considered the most thoughtful way. Unless you want a phone or x-box or whatnot, which is the way now.

Anecdotal evidence —

In this part of the world it appears that used / empty containers are more available and somewhat cheaper than 6 months ago. This may point to an over supply of empties. Price (via craigslist) seems to have dropped from $4K to around $3.2K.

And a suggestion —

Reengineer the containers to be foldable so that the empties take up less space. This would mean that a chassis could transport several empties in one trip and that more empties could be stored in the same space.

That said neither of the above will clear the bottleneck. This is very likely a dynamic problem that requires careful rapid, careful, study before proceeding.

No, people unload those containers. I can not imagine what would happen if one of it’s walls failed with workers inside.

What about using Bitcoin and Blockchain to solve the problem? After all, they are solutions in search of a problem.

Or mandates. I hear mandates work wonders motivating the poors and the deplorables to work harder.

Tunnels!

I met a Longshoreman today in the local Hardware shop, and asked about congestion at the LA/LB port,

His answer was that volumes of imports are up 2 to 3 times over 3 years ago.

He is one pf the workers who drive the ship loading and unloading cranes.’

My conclusion is that imports volume is greater than port peak capacity, and an overloaded port probably operates at less than peak speed. The best analogy I have is consider it a traffic jam, with a never ending rush hour.

Some solutions: Not a complete list.

1. Fix the bottleneck in port processing (probably requires construction)

2) Streamline the unloading process – Direct ship to truck or rail unloading

3. Live with it and hope volume drops after Christmas

4. Drop all empty returning containers in the desert between Barstow and Henderson.. Any truck can pick up a any container at the port and be paid for delivery.

“…volumes of imports are up 2 to 3 times over 3 years ago…” Why?

If volumes are indeed up by 2 to 3 times over what they were last year — what is going on? Is the u.s. consuming public 2 to 3 times more flush or 2 to 3 times more starved to buy stuff? If inventories were just-in-time small before the Corona crunch why does it take 2 to 3 times more stuff than usual to refill the inventories? Are all the businesses stocking deeper inventories now? Is there a crunch on storage space? What is going on? Were containers accumulating already before the present crunch — just at a slower rate? Is the u.s. exporting that much less stuff in containers than 3 years ago? Is Europe or Australia experiencing the same problems with their ports?

There are too many mysteries for me to fathom what is going on. What else changed between now and 3 years ago?

Inflation expectations are changing. Converting cash into things. Ask an Argentinian:)

It isn’t only the ports or truckers that are not moving things… but at least they aren’t storing or scrapping their highest cost capital items like the railroads

https://www.progressiverailroading.com/norfolk_southern/article/With-5000-locomotives-in-storage-Class-Is-wonrsquot-be-placing-power-orders-any-time-soon–20598

Note that UP and BNSF have the duopoly of rail service in the western US.

Precision Scheduled Railroading is primal asset stripping to goose share price. As posted here by Wolfstreet, railroads have reduced employment by 30% in just the past few years alone. And dozens of classification yards have been shut down and even ripped out entirely. With so much capacity willingly abandoned by railroad executives, there simply is not a surge capacity other than lengthening 2 mile long, 12,000 ton freight trains to 3 miles (and move even more slowly).

Once the physical plant has been destroyed it is nearly impossible to bring it back. There also is a serious lack of engineering, project management and skilled trades to “build back bettter”.

yea, odd how the market always fails huh? and in spectacular fashion, last time it was the gaming if the housing market. and we can see where that lead?

looks like a 2009 article

Sorry; google said it was a 2021 article when I did a search. I’d read in fan publications about parked locomotives, but those didn’t surface.

This is from FreightWaves in March 2020:

Note that in 2020, the 2 western railroads had as many as 6500 locomotives stored. Far more than GFC in 2009.

This map you might to join for free. There are no ports on Baja. Yep LB and LA are slammed Oakland not at all at this time. Portland and Seattle look normal. If you hit the minus you see how much is out in the pacific between here and China. Lambert didn’t you post a story on Copenhagen port the other day by far one of the largest in the world who doesn’t have this problem

https://www.marinetraffic.com/en/ais/home/centerx:-72.4/centery:46.4/zoom:2

Interesting is all the really bad laws on containers.

is it that or the lack of truckers to move the goods once they get to the US. if they dont move them, then they cant get off the ship, and it just keeps backing up from there

Several sources have said that “the shipping companies are no longer taking empties back”… When did that change and WTF?

Oh my, I am going to have to read up on that. One of the advantages of containers is that they can, and are, used repeatedly. IIRC, most of the empties are always taken back, if for no other reasons than they are paid to do or given discounts for future use, and more importantly, if there are no containers at the exporter’s port, there is nothing available to be ship. So, no shipping business. At least, that how it was for the company I worked at. Even if the problems were fixed next week at the port, we will still have backlogs at China, India, or Vietnam with people wait for containers to fill.

The average person can see all this and come up with solutions, so why cannot the Bozos supposedly in charge see this as well? Even in this corrupt, economic hellscape of a country having mountains of money and stuffing the ballot boxes will not get you (re)elected, if you screw up badly enough. It is not just Christmas gifts, but everything else an economy needs. Heck, American exports (the United States still exports a lot of goods) will be affected as well, if those empties are not available to be filled.

This is just repeating what everyone else is saying in someway, but I have to ask what is going on and why is a fairly straightforward issue like this not being dealt with? This would not have happened anytime in the 20th century.

My knowledge of the Port of LA is limited to watching “The Love Boat” re-runs, nor am I knowledgeable about logistics or possible facilities redundancy. But if intermodal container storage is an issue it seems to me the abandoned former George Air Force Base, now known as the Southern California Logistics Airport in Victorville, CA offers a possible solution. It is located 80 miles northeast of Los Angeles on the southwestern edge of the Mojave desert. Believe the site was considered for development of an intermodal facility by BNSF Railway back in 2007, but don’t know the status of that proposal.

Based on the Port of LA website, though, there seems to be pre-existing capacity: https://www.portoflosangeles.org/business/supply-chain/rail

My comment got snagged by moderation. I should’ve copied it. Here is the Cliffs Notes version:

Railroads have responsibilities in this mess. They all have adopted “Precision Scheduled Railroading”, which has radically reduced employment -30%, eliminated scores of classification yards where trains are switched and built, parked or scrapped 20% of locomotives from mid 2010s to today. Share prices shot way up, executives and hedgies profited. If you asset strip a quarter of your pre-PSR capacity, what happens? Once these capital and human resources are destroyed, it is difficult or impossible to restore. The only surge capacity railroads can do is increase train length from 2 miles to 3 miles, which they all are doing. A 3 mile long 15,000 ton train moves slowly. This was all planned and intentional; it is overlooked in the tweets that the ports and truckers are not cutting up cranes an5d trucks. This is perspective on how much locomotive capacity has been reduced:

https://www.progressiverailroading.com/norfolk_southern/article/With-5000-locomotives-in-storage-Class-Is-wonrsquot-be-placing-power-orders-any-time-soon–20598

Union Pacific and BNSF have 3000 locomotives stored, 25% of UP’s fleet. They are the duopoly in the western US. If you don’t like their service, go and find a truck.

William Vanderbilt, Robber Baron of the late 1800s: “The public be damned! We run them because we have to. They do not pay. … In that interview he was quoted saying: “Railroads are not run for the public benefit, but to pay. Incidentally, we may benefit humanity, but the aim is to earn a dividend.”

Great comments, cheers. I remember the WS piece(s), I think by “MC01” (who hasn’t posted in some time there, sadly).

BTW, I’ve noticed that if one takes too long to compose a comment in the little window, it often (not always) boots to moderation. You’re better off to cut/paste it after refreshing the page. That said, they’re *very* good here at clearing the queue. All hail NC mod genius!

BNSF was bought by Warren Buffett back in ~2010. He loves monopoly.

I’d argue this is a paradigm and dogma problem. The current system of goods flows is too complex, brittle, interdependent, and problem-based to operate efficiently, period. It isn’t just the US, it is Asia and Europe, too, all in the same stew.

It’s the end of an era, and all those solutions listed above won’t fix it. Period.

The first time I saw a shipping container was offshore, 1969, the year I went to see as a fisherman, off Nantucket. A cargo ship went by us bound to New York with these boxes on deck, many. Well, not boxes, actually, but truck bodies, stripped of chassis and wheels. It didn’t look like a ship but a floating box. Back then, most cargo ships were still the traditional high bow, midships house, curved stern design, beautiful, elegant, sweet. These were the ships of books by Joseph Conrad, Howard Pyle, Hammond Innes, cargo ships that took days, even weeks to load and unload, using deck mounted post cranes, block and tackle, swinging loads in nets or lashed on pallets into and from holds. When you sailed, your routine meant you spent most of your time in a port being filled or emptied, with periods then at sea running between ports. It took huge gangs to handle the cargo on the docks and of course theft was rampant.

The container changed all that. I banged around at sea and then ashore in the fish business during the 1970s and early 80s before taking a job at the Port Authority of New York and New Jersey, who had this idea of turning an abandoned 80 acre steamship terminal in Brooklyn, Erie Basin, into a big fish processing complex. They thought they could do this without partnering with the Fulton Fish Market crowd, which was a big mistake, and ultimately the project failed, for this and other reasons, and I ended up, then, in 1988, working in the container sector for the Port Department, mostly in the planning group. I knew nothing about containers. I knew they were truck bodies, I knew they could be loaded at the factory, sealed, and then shipped across the world to a warehouse or a store before being opened, entirely eliminating theft. More importantly, once specialized dockside cranes and container handling equipment were built, because whatever was being shipped was shipped in the same basic box, the loading and unloading of the ships took little time. Whereas it once took a week or even longer to empty and fill the holds of a cargo ship, now it took 10 to 24 hours to entirely remove and replace thousands of containers using three to seven cranes against the ship. Now, instead of a routine for sailors spending most time in port handling cargo and then periods sailing between ports, now sailors were aboard ships that spent all their time at sea except for the brief stops to discharge the containers.

By the time I was in New York container ships ruled the ocean, or at least the non-tanker and non break-bulk ocean. The first ships built to strictly carry containers, in the late 1960s, could carry maybe 800 40 foot boxes in special holds and on deck. By the late 1980s the ships could carry 3,000 40-foot boxes. By then a lot of manufacturing for the U.S market had moved out of the U.S, to Mexico but then Japan and Korea and then, in a huge wave, China, starting in the early 1980s. Containers were being carried from Asian ports across the Pacific to New York and the east coast not through the Panama Canal and then north but instead to the west coast, landed, and then placed on special double-stack (two containers high) trains for fast transfer to east coast markets. West coast ports exploded, and New York’s share dropped.

All through the 1990s and 2000s the mantra for those of us working at ports was bigger, faster, more efficient. Container cranes grew enormously high, could reach out 150 feet to lift and drop containers. The ships themselves grew to 8,000 TEU (20 foot equivalent) by the early 2000s, then 12,000, then 18,000 and more today. This was globalization, a fever to build stuff as cheaply as possible and then ship to established markets for sale in Walmarts and furniture warehouses and Home Depot and all the “big box” stores, everything a drive for scale, speed, consumption. Back in the late 70s when Japan began selling cars into the U.S. politicians panicked about the loss of jobs, the auto sector mainly, but somehow over the years this fear seemed to fade while in fact millions of American jobs went offshore to Asia (mainly) leaving local people without work, or work at much lower wages in service jobs. The U.S. heartland was hollowed out, with the full support of we who worked at ports, the political class, corporations, and the intellectual elite, everyone bewitched by the globalization dogma.

I went back to sea in 2012 at age 65, Ordinary Seaman, aboard a nearly 30 year old container ship the President Truman, an American ship, one of the last American merchant ships (there are just over 200 still sailing in the world fleet), at one time (1988) the biggest container ship in the world, the first too large to transit the Panama Canal, a ship which had for nearly all that time been ferrying containers between New York and other east coast ports (Charleston, Savannah, Norfolk) through the Mediterranean and Suez Canal to Singapore, with various stops in between, 60 to 70 day round trip voyages, one of several in a “string” of APL ships landing weekly at each port, promising fast and steady delivery. The truth is, when these ships came to the U.S they were filled with containers carrying stuff for the American buyer, but when heading to Asia, less so, with a lot of the boxes carrying just air, sending the empties back for more stuff. For a long time, for example, ships leaving Seattle for Asia carried, as “export cargo”, waste paper, cow hides, and garbage. Now, it seems, Asian countries are less enthralled with waste paper and garbage.

When I had worked for ports I spent most of my time building things, port facilities, mostly, before becoming an executive and making a lot of trips to see our container shipping customers in Asia and Europe, meeting in lovely offices overlooking lovely views and everyone trying desperately to meet the growing demand, maintaining and feeding an incredibly complex system of warehouses, trucks, ships, trains, data recording, and financing. Nobody ever, not once, paused and asked, can this go on forever?

I spent four years back at sea, on container ships and later military reserve ships. I made several round trips on the Truman, filling most of a year, until she was sold to breakers from India, nearly 30 years old, rusty, banged up, with 175,000 hours on her main engine. Those dreams of efficiency, so self-satisfyingly spoken of in those shipping CEO boardrooms when I had worn a suit, had a much different flavor after chipping rust, serving as ship’s carpenter, and standing watch, seeing directly how complicated and expensive it was – and is – to operate a ship. My last gig was as bosun aboard the USNS Shughart, taking her from her base in Violet, Louisiana on the Mississippi River to a shipyard in New York, not four miles from where I had worked decades earlier in the World Trade Center while at the Port Authority. It was more than a little strange to sail in to New York and see before me a Manhattan without those tall towers. When I had worked there I never imagined I would one day be on one of the many ships I had seen from the 64th floor all those years ago. Life is strange.

What is not strange, however, is what is happening now, and the growing realization that the entire era, and model, may be flawed. That complex just-in-time system of equipment and machinery works well – until it doesn’t. What the efficiency experts and pundits never see is that equipment – cranes and ships and trucks – requires maintenance and care and careful attention to detail, and without the required investment to keep things running, things don’t work so well if they work at all. As the years have gone on and we have built these complex systems we have failed to see that the net return for those last few percentage points of greater efficiency can never be reached; in fact, it seems that beyond a certain point of complexity things go backwards.

These days there is lots of concern about infrastructure, roads and water systems and such, as we see more and more evidence that systems built a half century ago require enormous re-investment. I have worked at three different ports, aboard several ships, and on a lot of fishing boats, and never, not once, did anyone choose to set aside what everyone knew was needed for maintenance and care. Not once.

Today the mantra may be changing – from globalization and just-in-time – to a new buzz word, sustainability. This is much in the news, with all these complex systems crowing about how they will reach zero carbon some time a generation or two in the future. It seems people fail to see what real sustainability is – equal in to equal out, something that will last over time, something that can be replenished, steadily. Sustainability is the opposite of growth, and we are still trapped in growth. The supply chain is cracking. Growth is cracking. Yet, until someone or some group has the strength and courage to change the paradigm, fully aware of the challenges and costs to build closed-loop, sustainable systems, it seems we will still cry that the supply chain problems are the President’s fault, or a corporation’s fault, instead of seeing that the basic paradigm – growth for the sake of growth, disposable products, waste, short term obsolescence – is itself flawed.

There are still water turbines in Washington state, installed over 100 years ago, that operate to generate power at hydroelectric dams, and they may last another 100 years. Back then, things were built to last. What is built to last today? Some people, perceptive, have chosen to find an older car, a car built before all the chips and glitz, something that has a basic engine and power train and some heat and a decent radio, a means of transportation instead of a self enclosed mobile entertainment system, a car built preferably before the year 2000. These days finding such used cars is becoming almost impossible. Obviously some people are getting it, the idea that it makes sense to have something simple, basic for the purpose, something that will last.

Maybe the goal of progress is not ever-increasing complexity but finding the most elegant, simplest solution. If the paradigm among us is shifting to that sort of approach, then what we will see in the coming years are enormous changes, but good changes, whereby all systems become simpler, more locally-sourced, sustainable. It is not going to be easy, or pleasant, requiring among many other things a corporate focus not on quarterly earnings and stock buy-backs but a long term – sustainable – approach. First, however, the dogma needs to change.

It’s not going to be easy.

Thanks. I expect that took you considerable time to write, and I know it took me time to read it carefully, but it was well worth it.

Sort of an obsession with me. I’ve written other stuff about this on my feeble little blog, check out “Sea Stories” https://charliesheldon2.com

I’m hooked, thanks Charlie!

So many great passages! I like this one a lot:

“I worked on military reserve ships. It used to be that such ships were staffed and manned by Navy personnel, enlisted men and women and officers, but somewhere along the way the decision was made to remove these ships and their staffing from the Navy and contract it out. This meant work for U.S. trained commercial and merchant sailors, of which I was one when I did it, but the main lesson I received from the ships I worked on was that they cost an absolute fortune to maintain and keep operational, and now that fortune included a hefty profit for the private contractor, too.”

Thanks for the link to your blog. I think you will start seeing a few responses to your blog posts from time to time. I have many questions about the sea and shipping, and the origins and nature of human culture and other topics you explore.

Hear here…

Your prose is appropriate of that of Richard Henry Dana albeit updated nearly a couple of hundred centuries after that cargo cult set sail.

Thanks for that comment. When you said ‘in fact, it seems that beyond a certain point of complexity things go backwards.’ I began to wonder if what we are dealing with is that we have reached a point of diminishing returns. So not matter how much more we push trying to ‘solve’ the problem, that we may have to step back a bit to effectively deal with it.

Thanks for this insightful and “grounded” (or whatever the seafaring equivalent might be) comment on material realities. I’m pleased that a post with almost no value-add elicited it!

Great stories. Great insight. And clearly a systems thinker who knows his Meadows leverage points well. I’ll bet you’d enjoy a fairly new book by Kate Raworth, another systems thinker trying to change the goal. It’s called Doughnut Economics and advocates, systematically ( ;) ), for those elegant, simplest solutions.

Thanks for your comment! A delightful and surprising read (I don’t think many people go from white collar work back to being a seaman).

Thanks for that Charlie. Some great observations there.

instead of seeing that the basic paradigm – growth for the sake of growth, disposable products, waste, short term obsolescence – is itself flawed.

Thanks for that fine first hand and the time you put into the post–and, imo, the big bottom line you stated above.

This…

Replace “equipment cranes and ships and trucks” with “crew” and you will have described the entertainment industry today and why members of the IATSE such as myself voted to strike. The producers are burning us out. We need time off. We need to eat. We need sleep.

WHERE IS EVERYONE!?

On a spiritual retreat and team building exercise facilitated by Marice Frost…

The crazy thing about this is that if there is one expertise that America has, it is logistics. Here I am thinking about the Pentagon supervising over a thousand bases scattered around the planet, all of whom need constant resupply. America’s ability to deploy forces around the world is not really about the soldiers sent but on logistics and the ability to deploy them anywhere. How about getting a team from the US Transportation Command to look over the situation and report back in a week on the gross situation and maybe some general solutions?

Thing is, so much stuff is made in China that this has to be effecting the profit line for the big corporations. Why isn’t Jeff Bezos screaming blue murder. Why aren’t the Waltons demanding Congressional inquires. Maybe I am missing it but you don’t rally hear much from people & corporations yelling about this. You have to ask too if some shipments are being prioritized and being sent for unloading in US Naval bases and I don’t mean just military gear. Has air freight picked up any? I have heard nothing about a demand for transport aircraft to bring in small, valuable loads in. Certainly they could bring computer chips in by the plane load on those huge transport aircraft you sometimes see. There appear to be several dogs not barking here.

A partial solution to the backlog on the West Coast USA may be the Port of Oakland. A google search, “port of oakland backup solution” yields several articles on the subject. My apologies for NC linking tool not working with my PC.

Maybe America had logistics expertise of a sort back in WW2. What America has had is obscene wealth that has allowed it to waste and squander to produce certain results that might appear as logistics expertise. Stupid money can always get results. Expertise seems something else to me.

The only expertise in this country today is grifting fraudulent paper fantasies and Ponzi schemes onto the next fool.

It seems the supply of fools may be dwindling. (Truckers who are unwilling to wait in line for free, for example)

I conclude that “optimization” and “just-in-time” sound wonderful and look good in a power point and are wonderfully efficient until they aren’t. In like manner my son (coding, systems, network applications, etc.) answered my question about the reliability of “the Cloud.” “Dad, it’s reliable until it isn’t.”And you never know when “isn’t” is upon you until it is.

Make it here. Make it to last. We used to know how to do those things until they were shipped elsewhere and optimized.

Being an ancient US Army Supply Specialist, before I read the tweets, I came up myself with a couple of the listed cures for ending the Southern Cal port blockages. The fix is not rocket science.

The reference to the Romanoff’s monarchy is apt. Their corruption, incompetence and WWI led to the 1917 revolt. The exploitative just-in-time logistic system has collapsed. The invisible hand cannot fix it. The current ruling cult is sitting around waiting for the economy to cure itself. The government doing anything to fix it is heresy to them.

Additional remedies;

1) If the railroads will not get rid of Precision Railroading, take them over for the duration like in WWI.

2) Form a national Trucking Corps. The federal government hires (or drafts) twenty/thirty year olds. Have month long training courses for the Corp to learn to drive and backup Semis. Weed out the losers. Pay them family supporting wages and let them do their jobs until the crises is over.

3) Government rents idle trucks and chassis, builds Liberty Trucks without computer chips for use only if necessary, assembles more chassis, and constructs container storage yards along railroad main lines out in the boonies.

The global jet-set had better get their heads out of the sand; otherwise, it’s the lamppost for them, like before.

I beg to differ with Mr. Petersen’s choice of most capital intensive part of the line is the container crane. It is the Ship! Charter rates for 8500 TEU vessels are over $100,000/day and you have 76 of them at anchor waiting. Taking previous year’s figures, LA/Long Beach are capable of handling 18 boxes/minute or about 26,000 per day or clear about six 8500TEU vessels per day.

Find some space on government land and drop off all empties until anchorage fleet disappears.

Interesting on container ship charter rates. I doubt the terminal operators are paying that cost!

I recall a container stuck at the Long Beach terminal some years back. The company I work for imports from Germany. A dispute between the terminal and union at that time caused a slowdown.

Worked great for the terminal. They charged something like 500 to 1000$ per day to store containers, so the longer it took the more the bill was for the importer.

It would be interesting to see the lease/charter contracts for these vessels and the containers they carry. I don’t know about now but it used to be a standard clause in a shipping contract to cover something called “demurrage”, a charge payable to the owner of a ship for failing to unload or discharge a cargo within the time agreed.

But its great optics isn’t it? We see those ships backed up at the ports on the nightly news and think, oh yeah, that’s what’s wrong with the economy. No wonder I can’t buy this or that and prices on everything are going up and up, after all, it’s the supply chain, got it? And lack of truck drivers, Sheeez! Just look at that LA port, what a mess.

You only get to see what they want you to so 24/7 we have this great visual and verbal explanation to why this terrible situation is occurring off our shores, no wonder.

It couldn’t be we lost an unwinnable trade war with China even though we put tariffs on 80% of their exports resulting in prices across the board rising, could it? Or sanctioned the heck out of every trading partner we ever had and maybe, just maybe there might be some sort of retaliation by laying siege to the “supply chain” from fed up manufacturers. Wait, do we make anything in the US anymore?

Or like another poster said, maybe it is us slowing it down in some sick way to teach those uppity global suppliers what’s up? Either way you can just about bet on this going on long enough for them to roll out a pre arranged solution to this problem of their own making and it probably is going to be well received once everyone’s faces have been ripped off from the inflation this has caused.

The comment about few cranes in use made me wonder if many are down because they lack spare parts that can’t be obtained. Does anyone know if the cranes go down easily? What kind of maintenance and spare parts do they require?

Almost all of the port problems in LA are being driven by shipping companies and the price/leasing rate of containers. After the COVID-19 lockdowns last year, empty containers are scattered all over the world in places where they shouldn’t be. In Asia the price/leasing rate for containers have come down a great deal compared to last year (even though they are still leasing at a historically high price). But the rate of shipping contracts from China to the US is now 3 or 4 times the rate for the return trip because of pent up US demand for imports. They have no incentive to wait and get loaded back up with US agricultural products. And their incentive to be loaded up with empty containers has declined as well. So they have a perverse incentive to unload their freight here as quickly as possible and return back to China so they can do the next China to LA run in record speed. The same thing happened last year but it’s even worse this year because imports exploded and the price of containers has come down a bit. At the same time with the way demurrage fees work, I am unconvinced that either the port or the shipping lines have a clear motivation to really turn this problem around … a clogged port is a goldmine of fees that usually wind up being paid by the merchant.

hm, we seem to be ignoring the problem is that the port can offload the ships to warehouse space in the port, but trucks take from the warehouse to its end destination, and we can tell the problem is the last step, since ships are backing up on the coast, because there isnt room to store their shipments at the port, because the last step isnt happening. the why of that could be because trucking companies have treated their workers so bad, poor working conditions (seems they can be gone up 2 weeks from home, which might be ok for singles, but tough for married couples….especially if they have kids. makes it so the trucker doesnt really see their wives or kids..then there is the pay issues, truckers like jut about all other jobs, havent had much in the way of pay raises…in a long time… also tends to make it so that the jobs arent exactly popular with potential new workers, and current ones start to look really serious at retiring

plus of course there is that large increase in package delivery driver…since that work tends to be more local, (they are at home more often, pay may actually be better)

if we decide to use the military to solve this problem for businesses, who will pay to have it done? will the DOD bill for hours worked by the troops to trucking companies? maybe if they set the rates high enough, that will the get the message through the trucking companies to do some thing. if you have been to LA, you know that there isnt a lot room to add more space to store containers. while maybe worse in LA, its not unusual for ports, since they usually get established very early in the life of a city. and can only exist n a few places (while there is a lot of coast line, there isnt a lot places where ships can unload and load goods

I don’t think Petersen’s really thought threw the using trains to haul the containers to a location within 100 miles. From Lambert’s query about rail CEOs worrying about diverted resources, I’d bet you’re talking only a couple engines. And here’s where I think Petersen has miscalculated in this area. Assuming you have a 500+ acre government site within 100 miles of the port, how many sets of track run by it? At most I’d be wiling to bet it’s 2. Are we saying we’re going to now create a temporary rail yard here? Are we assuming it’s not just a short line extension so you can loop the locomotive around? The odds are the desired location as stated by Petersen is one set of tracks with no easy way of looping the train around which means it’s one train in, one train out. We’re not talking trucks here that can easily pull onto the shoulder if need be to pass each other, we’re talking 1 train per set of tracks. In order for 2 trains to pass one one set of tracks you need a siding at a minimum. If you’re using trains it’s actually probably more likely to succeed if you do take everything to Dallas because at least then you’d be far enough away to be able to create a loop so you can leverage more locomotives. Of course you probably could get that loop by picking a closer city or 2 also.

I’m curious about this, as in Hawaii we are dependent on container shipping and locals are pretty attuned to transportation issues, leading to panic buying. So far, nothing. Due to Jones Act requirements mainland to Hawaii shipping is restricted, so we have a single dominant carrier (Matson Lines) who ship from their partly owned terminals in Long Beach, Oakland, and Tacoma. Whatever is happening in the ports, it isn’t affecting Matson. They also reported record profit last quarter which they attribute to a new China – Long Beach service using leased ships so it isn’t affecting that (at least from a profit basis).

I have read other reporting that the problem is California environmental restrictions on trucks which limit the number of trucks that can legally operate there.

I see they are looking at Port Hueneme. Used to live there. The port is pretty small (not sure but maybe one or two berths only). When I was there it was mostly used by car carriers who leased space on the naval base. There was a short line railroad that IIRC was operated by Ventura County that moved railroad cars around the base where they were loaded out then transferred to I guess SP. The base is the west coast SeaBee base (so full of civil engineers) and during WWII was the point for shipping civil engineering equipment to the Pacific Theater so it has a lot of lay-down space.

Meanwhile Amazon chartered a bulk carrier that was able to convert deck space to containers which Amazon sent to Houston.

This article is unbelievable… and just what I was afraid of. The bottleneck situation is very complex but the issue of how to handle and store “backhaul” empty containers heading for China is straightforward and relatively easy. We need 500 acres of flat, solid US. government-owned storage within 100 miles of the LA/Long Beach ports with road access and very good rail connections and multiple tracks within the facility for offloading containers.

From 1924-36 the Army Industrial War College in Washington, DC planned the WW II mobilization in exquisite detail. Training airfields and production plants- always complete with excellent freight rail service- were placed all across the southern US from LA to Charleston. For a quick look at the LA/Riverside/Mohave complex go to https://en.wikipedia.org/wiki/California_World_War_II_Army_Airfields and start reading.

Or don’t bother The obvious answer to “Where do we store the empty containers?” is March AFB, the old SAC base in Riverside, CA,. 2,000 unused acres complete with infrastructure and 12,000 foot runways four feet thick. Look at the Burlington Northern Santa Fe route map at https://www.bnsf.com/ship-with-bnsf/maps-and-shipping-locations/index.page. The little orange line running south from San Bernadino goes double-tracked right into Riverside, CA and March AFB. And the mobilized National Guard soldiers emptying the trains would operate only on US. Government property and have nice barracks to stay in. There are at least a dozen other abandoned WW II fields out there, all with rail connections. But March is best for containers stuck in LA and Long Beach.

Even better take the Union Pacific double decked container trains coming back from Houston and turn them left at Colton, CA to unload and sort the empties at March to relieve the pressure. https://www.up.com/aboutup/reference/maps/system_map/index.htm

Then every night run trains from March filled with empties designated for one ship heading to one of the five huge Chinese container ports and deliver them straight to the cranes (which may be more of a bottleneck than I anticipate). And use government emergency power to administratively bypass the shipping companies’ “not our container” rule.