By Jerri-Lynn Scofield, who has worked as a securities lawyer and a derivatives trader. She is currently writing a book about textile artisans.

Few consumers step into electronics store thinking, “I’m looking to buy a lemon today. One that’s difficult to repair and which I’ll have to throw away and replace when it breaks.”

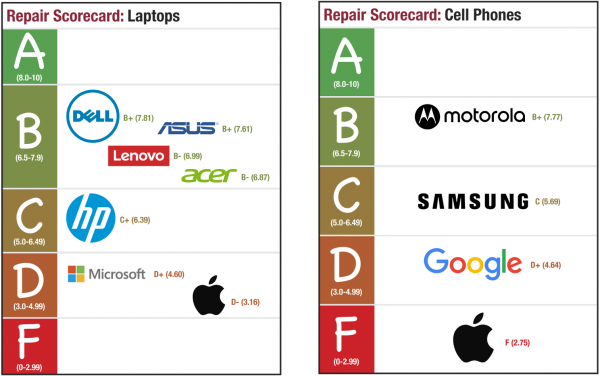

Many consumers would opt to purchase electronic devices that last and could be easily fixed. The problem: at present, they don’t know which products so qualify. Yesterday, US Public Interest Research Group (US PIRG), a public interest group active on the right to repair front, issued a scorecard, Failing the Fix, ranking products of the most popular cellphone and laptop makers.

Source: US PIRG, Failing the Fix, March 2022.

These charts merely summarizes manufacturer repairability scores. The full report includes more detailed information, assessing six criteria. The report is short and I encourage readers to read it in full – especially those readers who are mulling purchasing a cellphone or laptop.

Dodgy products aren’t just an individual problem, but a leading component of the mountain of waste the world – and especially the U.S.- generates. Per the report:

Electronic waste is the fastest growing waste stream in the world, and the U.S. EPA reports that it is now the fastest growing part of our domestic municipal waste stream. Americans spend nearly $1,500 on new electronics per household, per year – and could save a combined $40 billion if they were able to repair instead of replace products and extended lifespans by 50 percent.

To help consumers pick more fixable products, since January 2021, France has required manufacturers to provide a repair score, ranked from 0 to 10, for all products. In collaboration with iFixit, US PIRG used the French scores for 187 products as part of its scorecard ranking ten manufacturers. In addition, according to the report:

Because repairing products is dependent on your ability to get access to necessary repair materials, our grade also reflects companies’ record of lobbying against Right to Repair, or membership in associations which are prominent Right to Repair opponents.

Consumers who seek to purchase easily repairable products – especially those from companies who do not fight to prevent Right to Repair – can use these grades as a starting point for making those evaluations.

Additionally, an analysis of what aspects of repair score higher or lower by manufacturer, such as parts pricing or repair documentation, can help consumers understand what repair challenges might be, and also help manufacturers best address their repair shortcomings.

The Bottom Line: Laptops

The report didn’t mince words and named names:

Dell ranked highest for the ease to disassembly, despite Lenovo recording the best overall scores in the French index. Microsoft devices are much more physically repairable than their French scores might lead you to believe – however, because access to documentation and parts is limited, those devices lose points to result in a 3.87 average grade across their current models for sale in France.

Apple lost the greatest number of points for their active lobbying against Right to Repair and support for other trade groups who are most visible in opposition, with Microsoft also losing points for direct lobbying. Lenovo received the highest scores for availability of documentation (service manuals), as well as parts pricing and availability.

The Bottom Line: Cellphones

The report separately assessed the repairability of cellphones, and generated a different scorecard:

Looking more carefully at the contributing factors to our grade for cell phones, we again see some disparities between the total French repairability index and the physical ease of opening the device. Samsung had the highest overall score, but a considerably lower score on ease of opening the device relative to Motorola. Apple and Google lost the most points due to their engagement in opposing repair-friendly legislation.

Across the 62 phones we scored, the average total French repairability score was 6.94, and the highest score belongs to the Samsung Galaxy A03s with an 8.4 – but the device only scored a 9.4 out of 20 for disassembly. That’s slightly below the average disassembly score of 9.9. The phones tied with the highest score for disassembly are the Motorola Moto g10 and e7i Power, both with 18.9 out of 20 scores.

Yesterday, I spoke to Nathan Proctor, senior right to repair campaign director for US PIRG, and author of the report. The pandemic has made people much more aware of the right to repair, as they’ve become increasingly dependent on their laptops and mobile phones. “We’ve never been so reliant on our phones and laptops to work or learn, “ Proctor said. “But when we needed repair the most, many manufacturers took their toys and went home. Apple stores were closed for months when repair needs were most urgent, while smaller shops stayed open.”

In many cases, this meant Apple stores shut, while holding hostage devices consumers had brought in for repair. I didn’t suffer so, but in January, I had to pony up for a replacement laptop, when my laptop suffered a repairable screen crack. Alas, Apple stores remained closed for repairs and the only authorized repair centers an Apple agent could find had a one week wait for repair. I couldn’t be without a device for a week – or longer – especially as when it broke, with no access to repair services it was uncertain whether the device could be repaired and might have to be replaced anyway. (It was fixable, and I’m using it as a back-up machine.)

This experience will shape my future purchasing decisions. The release of repairability info in France has also affected consumer attitudes. Per the Failing the Fix report:

On behalf of Samsung, OpinionWay investigated how the French repairability index has influenced French consumer attitudes and behavior since its introduction January 1, 2021. Among the key findings are that 71% have heard about the index, and 86% say that the index impacts their purchasing behavior – including 8 out of 10 who indicated they would give up their favorite brand for a more repairable product.

“We hope consumers who don’t want to left out in the cold waiting for a repair will use this guide,” Proctor said. “If you have a Dell computer, you had a very different experience looking for a repair during the pandemic than if you had one of the more restrictive manufacturers we reviewed.”

Ongoing Battles on the Right to Repair Front

The right to repair isn’t just important for consumer electronics. It’s also vital for farmers. “Repair restrictions hurt resilience. We need our phones and laptops, they’ve become essential to just getting through the day, Proctor said. “And it’s not just Apple’s repair restrictions that are concerning. John Deere is pursuing a similar model.”

For farmers, timing is everything. That simple fact has major implications for the right to repair. “[I]n the world of agriculture, everyone is using their equipment at the same time. If your farm is planting, all the local farms are planting. If your farm is haying, everyone is out haying,” Proctor said.

He continued:

Because John Deere equipment is reliant on the dealer for many repairs, dealerships develop repair backlogs during critical farming windows. Our devices are critical infrastructure, without which we can’t work, or attend school or feed society. We view Right to Repair as essential to protecting that infrastructure.

US PIRG has expanded the battle for a right to repair for farm equipment by filing a complaint against John Deere with the Federal Trade Commission (FTC). Deere currently accounts for 50 percent of U.S. tractor sales. That agency has upped its support for the concept, especially after the appointment of Lina Khan as its chair in June 2021 (See Biden Taps Lina Khan to Chair the FTC, FTC Votes 5-0 to Crack Down on Companies For Thwarting Right to Repair, and FTC, Where Art Thou?: Appliance Manufacturers Routinely Invalidate Warranties if Customers Use Third-Party Repair Services).

According to an article last week in Motherboard, Right to Repair Groups and Farmers Unions File FTC Complaint Against John Deere:

A public interest research group, farmers unions, and right to repair advocates have filed a complaint with the Federal Trade Commission against John Deere, alleging the tractor manufacturer intentionally makes its products difficult or impossible to repair except at Deere dealerships, making it a monopoly and thus operating in violation of the Sherman antitrust laws.

“While historically Deere has outcompeted rivals to win farmers’ and ranchers’ business, in recent years it has resorted to leveraging its monopoly power in the market for large agricultural equipment to dominate the repair market for its equipment,” the complaint says. “A farmer who purchases Deere equipment today may not realize that Deere, under the guise of technological advancement, has made it impossible for farmers to make important repairs themselves or to go to an independent repair shop. Even where purchasers of Deere equipment are aware that Deere requires important repairs to be performed only by Deere-authorized technicians, Deere’s market dominance leaves these purchasers little to no choice but to submit to Deere’s terms.”

The root problem here is industry consolidation. Per Motherboard

The complaint is asking for formal acknowledgment of what many farmers have been arguing for years: that Deere has cornered the repair market using a mix of digital rights management and its increasingly consolidated dealer network, where most repairs must be done. According to a recent U.S. Public Research Interest Group report—the same group that filed the FTC complaint—more than four out of every five Deere dealers is part of a chain of dealers of seven or more locations. This “mass consolidation,” as USPIRG put it, means that there is one dealership chain for every 12,018 farms and every 5.3 million acres of American farmland. The result is that many farmers have no real choice about where to get their tractors repaired, since all the repair centers near them that can do the repairs are increasingly owned by the same company, which are ultimately part of Deere’s larger network.

Deere has in the past promised to fix some of these abuses – but hasn’t. It’s now high time for the FTC to act. According to Motherboard:

The complaint further alleges that Deere has engaged in “unfair and deceptive trade practices” by claiming it would change these practices but then never actually doing so. In 2018, an industry group representing tractor manufacturers including John Deere said that by January 1, 2021 the companies would make repair tools, software, and diagnostics available to the masses. But that never happened. When shareholders questioned Deere about that, the company blew them off.

More broadly, US PIRG is also pressing for state and federal legislation to enshrine a statutory right to repair. Nineteen states are currently considering right to repairs, according to a US PIRG blog post, Industry scrambling to slow Right to Repair movement as momentum grows.

Passing new legislation isn’t easy. “I would say there is growing awareness and support, but overcoming the opposition of the vested manufacturers is really hard,” Proctor said. Nonetheless, he’s cautiously optimistic, “Passing a bill will take a lot of hard work and some good fortune — but we’ve passed the point of no return. Right to Repair is here to stay.”

Until either significant state legislation is passed FTC actions prod manufacturers to improve the repairability of their products, the only option for aware consumers is to pay attention to information such as Fixing the Fix’s scorecard in guiding their electronics purchasing decisions.

A problem with repairing many things is it isn’t cost effective.Most products have a built in shelf life. As it ages repairing isn’t advisable because the cost is usually excessive. You will be spending a lot to fix something that will probably again break in a short time. You then have to spend for a new product making the repair cost a waste of money. Appliances are in this category. If certain parts fail it cost as much or even more than the cost of a new product. I had a washer that broke while still under warranty. The repair person showed me the repair bill. It was mr than I paid for the washer. It broke again shortly after the warranty expired.At that point I replaced it with a new different brand washer. I initially bought the washer because it was rated very high by Consumers Report. We live in a disposable society by design.

We get the behaviors we incentivize. If repairability is a priority then we need to reward it and penalize the undesirable behavior. Unfortunately the levers for such from a legislative perspective are held by those who perform those undesirable behaviors and profit from them. The only way we can vote is with our money. I type this on an 11 year old laptop for example and in as many purchases as practical I buy used or that which will last and/or can be repaired. If enough people did so, behaviors would change.

That said, an industry move to a short list of standard batteries would dramatically increase the repairability of mobile phones. Thus suppliers would need to build only a handful of different models and new stock would be available for all phones. All of my “upgrades” in the mobile phone department have been brought about by a lack of usable replacement batteries. How to force this behavior?

As another person with an old laptop, standard batteries would be nice there too.

If you have a product that is designed with serviceability in mind (and accompanied by a good repair manual), you can often repair things yourself. That’s where the big savings happen. Last year I repaired a dryer myself, with the only cost being a $10 timer widget from e-Bay.

But when repairs have intentionally been made difficult, you end up with the unhappy choice you faced: An exorbitant bill for a repair done by a third party or dealer, or a complete replacement of the product. I think legislation would help here.

And in the world of computers (both desktop and laptop), serviceability correlates very strongly with upgradeability. I’ve helped several people get more years of service out of older laptops by adding RAM and replacing the old hard drive with an SSD. Some of the computers were trivial to upgrade. Two screws and I was done. Others were appallingly difficult, requiring the removal of 30+ screws, multiple delicate ribbon cables, and other devices. Upgrades became riskier. And still others could not be upgraded at all, as the RAM and storage were soldered to the motherboard. Insufficient RAM? Sorry, go buy a new computer. Have fun with the data migration!!

There are lots of 10-12 yr old PCs that can be upgraded with a decent SSD and 16GB of RAM for less than $125. If needed, toss in another $25 for a used 4 core processor and it’s nearly as good as new. But it is hard to find out how your machine can be upgraded.

Typically motherboards are designed to be upgraded with larger, faster RAM as well as faster more efficient processors and graphics cards which haven’t been released. But the computer owner’s (user’s??) manuals only describe the components that were validated to work on the machine when designed, not those that invariably came along a bit later. My 2011 Dell’s manual claimed it only worked with 2 core processors and 8GB of memory. I’m using a 4 core processor,16GB of RAM and Windows 10 in the machine today. As someone who didn’t know anything about upgrading, I found the information very difficult, but not impossible to obtain. Seems reasonable to require manufacturers to disclose planned but unverified upgrade paths upon purchase then update the owner’s/service manuals as the new components are verified to work in the machines.

Youtube videos have made repairing many things trivially easy. I recently replaced the clutch on an older Whirlpool top-loader and it was not problem since I didn’t have to figure out how to get things apart thanks to the vids.

As for laptops, BITD they were large and clunky but had removable doors for memory, storage, and battery. HP had some excellent online documentation. I easily replaced a keyboard on one. But now I think thanks to Apple we need small and sleek so you have to figure out how to separate the laptop case to get into it, and then things like connectors require pretty good dexterity to separate. I have a bad battery on a recent HP x360 but even watching the video I hesitate to try to pry the thing apart.

For consumer electronics I’ve had to replace crappy Chinese capacitors in the power supply boards with good Japanese ones. Again, youtube and online discussion boards to the rescue.

I’m very sorry about having to replace your laptop,

Unfortunately, after spending $4,000 to upres a 30-minute video edited in Final Cut Pro 5.4 which was not even editable in Final Cut Pro 5.5, much less Final Cut Pro X (which when it was released, immediately rendered millions of dollars worth of edited video into digital paperweights), I had the grim realization that Apple’s policy of planned obsolescence makes 1950s Detroit look positively amateurish.

As much as I dislike Microsoft, I can still easily edit Office files created in 1985.

Now you can’t even edit Word for Apple files created a few years ago. And heaven help anybody who needs to convert even moderately complex .pages documents into Word.

Anyone who buys Apple computers should be warned that in just a few years, you will not have access to the files (or possibly even the drives) with the work that you are creating today.

Yes. Apple SSDs in the M1 series are just some chips soldered onto the motherboard, so if you want a new drive you will need a new motherboard. Not to mention soldered-in RAM and general unrepairability.

At least they switched away from the butterfly keyboards. It must have been expensive replacing half the glued-together laptop every time the keyboard died.

I understand that this may not add anything to the thread, but with Microsoft and Google receiving D pluses I feel compelled to share this clip: https://youtu.be/3Q3FXIchE-c?t=60

I’ve been pushing pretty hard to get the techs set up for board repair where I work. This use to be a fairly routine activity, but fell out of favor because it was cheaper to replace the whole board. Now, we cannot get the boards, cannot get repair parts and most of the techs that were good at board repair have retired, and getting young techs up to speed on this will be very, very difficult.

When an MBA comes to you with a better way to save money, just tell them to go back to their cubicle and stay away from the real world.

Niche laptop player, but with repairability as a core feature: https://frame.work/

I’ve had one of these for months now, and love it. HIGHLY recommended.